Grain Drying & Climate Control

Bridgview Farms – grain management system with three of six 2000-1200 central heating modules (total of 6 million BTU/H output) set up to dry at twenty-four 20,000 bushel bins.

Learn more about the DryAir Grain Drying System at Assié Ag Products:

The DryAir system will provide safe and efficient delivery of heat for a number of agricultural applications”

Grain drying – Use DryAir solutions to dry the grain in your bins Climate Control – DryAir offers permanent or temporary installations for grain temperature and humidity control. Expanding Your Harvest Window – Convert your aeration system into a effective grain drying system. Systems can be sized for your specific application:

- Single central heating module system using manifold & hose distribution to multiple bins.

- Once set up, the DryAir system can also be utilized for temporary heat to your shop and out-buildings.

- Large grain managements systems utilizing multiple central heating modules and permanent, insulated fluid circulation lines.

Contact for Grain Applications please call 1-888-750-1700

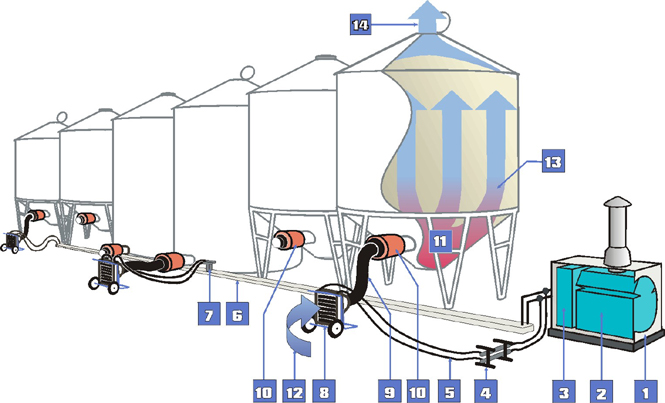

How it Works

- Central heating module

- Hydronic water heater

- Pump & controls

- Circulation manifold

- Flexible circulation line

- Fixed insulated circulation lines

- Quick coupler circulation hook-up

- Heat coil assembly

- Air tube

- Aeration fan

- Plenum

- Intake air

- Heated air

- Saturated air

In its simplest form the system consists of the following:

- The central heating module encloses a natural gas fired hydronic water heater, pump and controls.

- The hydronic water heater heats a water/glycol solution.

- The pump then circulates the heated solution out to remote heat coils at the bin.

- The heated solution circulates through the remote heat coils.

- The heat coils are made up of a circulation heat coil and an air tube. Universal aeration fan adapters are mounted to the aeration fans and allows a quick hookup to any aeration fan already in place at the bin.

- Heat is transferred as outside air is drawn over the heat coils by the aeration fans.

- The heated, “desert-dry” air is then delivered to the bin via the flexible air tubes.

- The air travels through the grain, captures moisture which is then flushed out through vents at the top of the bin.

- Air diffusion within the bin is accomplished using conventional plenums currently being used with natural air drying and aeration systems

Subtle Advantages… Significant Gains

You may not be aware of the subtle advantages gained by incorporating a DryAir system into your operation. The gains in profitability can be very significant!

Gentle On Sensitive Seeds... Improved Germination

Optimal Bin Environment!

Reduced Stress!

- A decreased stress level associated with the ability to get the crop off even though it was not dry

- The ability to easily and reliably deal with the moisture in the bin, ensuring product quality.

Warren Potter from Hoey, Sk. commented “After using DryAir for one season made us appreciate the safety and simplicity of the system. Reducing stress is important to us all, and I believe DryAir helped make last fall the most enjoyable fall we have had in a long time”.

Potentially Replace a Second Combine!

Duplicate Perfect Natural Air Drying!

Utilize Equipment you Currently have in Place!

Harvest Earlier and Increase your Harvest Options!

Safe & Cost Effective Dry Down!

Help Maintain Grade, Germination Quality & Optimum Test Weights!

The Optimum in Safety!

Maintain a Safer Bin Environment!

No Moisture Added from the Combustion Process!

- Natural Gas 9.30 lbs. /100,000 BTU

- Propane 7.77 lbs. /100,000 BTU

Clean, Contamination Free Drying Results!

Utilize as a Central Heating System!

Utilize as a Mobile Heating/Drying System!

Accurate Drying Predictability!

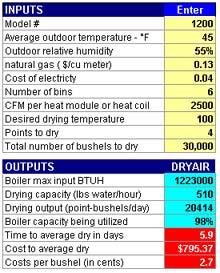

Drying Predictability

“We´ve invested a great deal of time in developing the tools needed to take the guess-work out of in-bin drying. Predictability is a very important part of a good drying system. Our whole goal is to minimize the difficulties a producer faces with grain management” says Claude Bourgault, President of DryAir Inc., DryAir offers a computer program that will calculate a whole range of results including “emerging air temperatures”, “drying times” and “costs per bushel” (See the “Outputs” chart, to the right.) With this unique tool, a producer will now know when drying is complete and will be able to better manage his product in the bin. The “outputs” are the result of the correct “inputs, most of which are readily available. Historically, the most difficult and critical to obtain is air flow . DryAir provides unique measurements tools in the form of built-in air flow grids that provide producers with the accurate CFM readings required for accurate drying time predictions. If you don´t have a computer, accurate drying time calculations can also be done utilizing manual charts.

“We´ve invested a great deal of time in developing the tools needed to take the guess-work out of in-bin drying. Predictability is a very important part of a good drying system. Our whole goal is to minimize the difficulties a producer faces with grain management” says Claude Bourgault, President of DryAir Inc., DryAir offers a computer program that will calculate a whole range of results including “emerging air temperatures”, “drying times” and “costs per bushel” (See the “Outputs” chart, to the right.) With this unique tool, a producer will now know when drying is complete and will be able to better manage his product in the bin. The “outputs” are the result of the correct “inputs, most of which are readily available. Historically, the most difficult and critical to obtain is air flow . DryAir provides unique measurements tools in the form of built-in air flow grids that provide producers with the accurate CFM readings required for accurate drying time predictions. If you don´t have a computer, accurate drying time calculations can also be done utilizing manual charts.

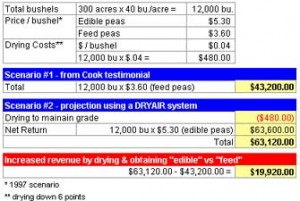

You do the Math!

“I started my 1997 harvest the third week in August harvesting peas. I filled my aeration bins with 20 – 22% moisture peas” says Dave Cook of Kinistino, SK, “I had a 1/2 section of greens testing 20% moisture with no aeration bins left so, not wanting to put them through my Vertec dryer, I decided to take some wheat testing 17% instead. I figured I could hold the wheat until some aeration bins were free or run it through the dryer.” Cook said he returned to his peas when they were dry but they had already bleached. No rain had fallen on the fields… just heavy dew at night and hot sun during the day. These peas went as feed. The peas that had been removed earlier and aerated went as edible. It worked out to a difference of $1.70 per bushel from edible to feed. Today, Cook has a DryAir 2000 system on his farm. He has more than doubled his existing aeration capacity and has reduced the risk of experiencing that kind of loss again.

“I started my 1997 harvest the third week in August harvesting peas. I filled my aeration bins with 20 – 22% moisture peas” says Dave Cook of Kinistino, SK, “I had a 1/2 section of greens testing 20% moisture with no aeration bins left so, not wanting to put them through my Vertec dryer, I decided to take some wheat testing 17% instead. I figured I could hold the wheat until some aeration bins were free or run it through the dryer.” Cook said he returned to his peas when they were dry but they had already bleached. No rain had fallen on the fields… just heavy dew at night and hot sun during the day. These peas went as feed. The peas that had been removed earlier and aerated went as edible. It worked out to a difference of $1.70 per bushel from edible to feed. Today, Cook has a DryAir 2000 system on his farm. He has more than doubled his existing aeration capacity and has reduced the risk of experiencing that kind of loss again.

Safe Moisture Removal in a Commercial Processing Application

The DryAir system also lends itself equally well to safe moisture removal in commercial processing applications. Tisdale Alfalfa Dehy Ltd. of Tisdale SK is a farmer-owned and operated alfalfa dehy processing plant. The company’s main production includes 1/4″ dehy and suncure pellets along with 7/8″ and 1 1/4″ long fiber cubes produced from alfalfa bales. “Until recently, the cube operation had been limited to the summer production line.” says Peter Fofonoff, General Manager of Operations “With increasing demand for year round supply of product, production had to be extended into the winter months.” Fofonoff says that before this was possible, there were moisture removal issues to deal with. As part of the production operation, moisture must be added to the product during the cube forming process. Normal removal of cube moisture is performed in a cube cooler/drying chamber by forcing outside air through the moist cubes. During the summer months, outside air is warm and moisture removal is not a problem. In sub-zero conditions, the cubes will freeze rather than dry, resulting in an unsatisfactory storage and shipping situation. The key to selecting the DryAir system over other dryers was that the fire risk was nil… a very important factor as the cube production line and storage facility are all under one roof. “Moisture was successfully removed from the finished product to the desired 9 and 10% moisture levels… even at -30°C.” says Fofonoff, “The product is coming out with as good a results as the summer production. The DryAir system allows for the output of 7 to 8 Metric tonnes of product per hour with absolutely no fire risk. The cost and economics of the system can be measured by the constant supply of product to our markets with strong dollar returns.