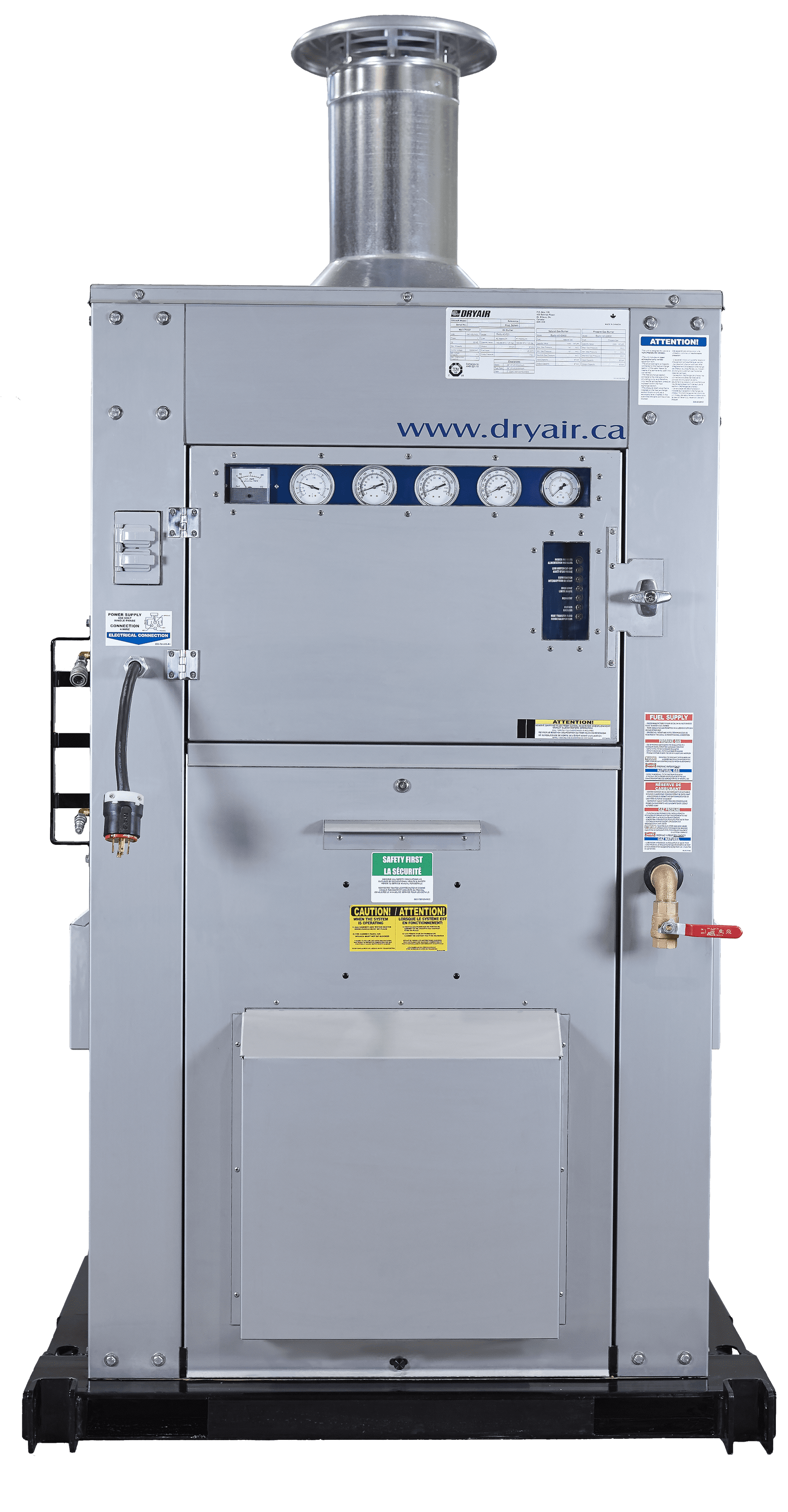

- Fuel: LP, NG or Tri-Fuel: Diesel, LP or NG

- Input: 896,000 Btu/h

- Heat Area: 27,000 ft²

- Thaw Area: 15,750 ft²

- Cure Area: 36,000 ft²

- Weight: 2,800 lbs dry, 4,100 lbs wet

- Dimensions: 64″ l x 57″ w x 98″ h

- Optional lift frame available

* Burner change required to switch fuel source.

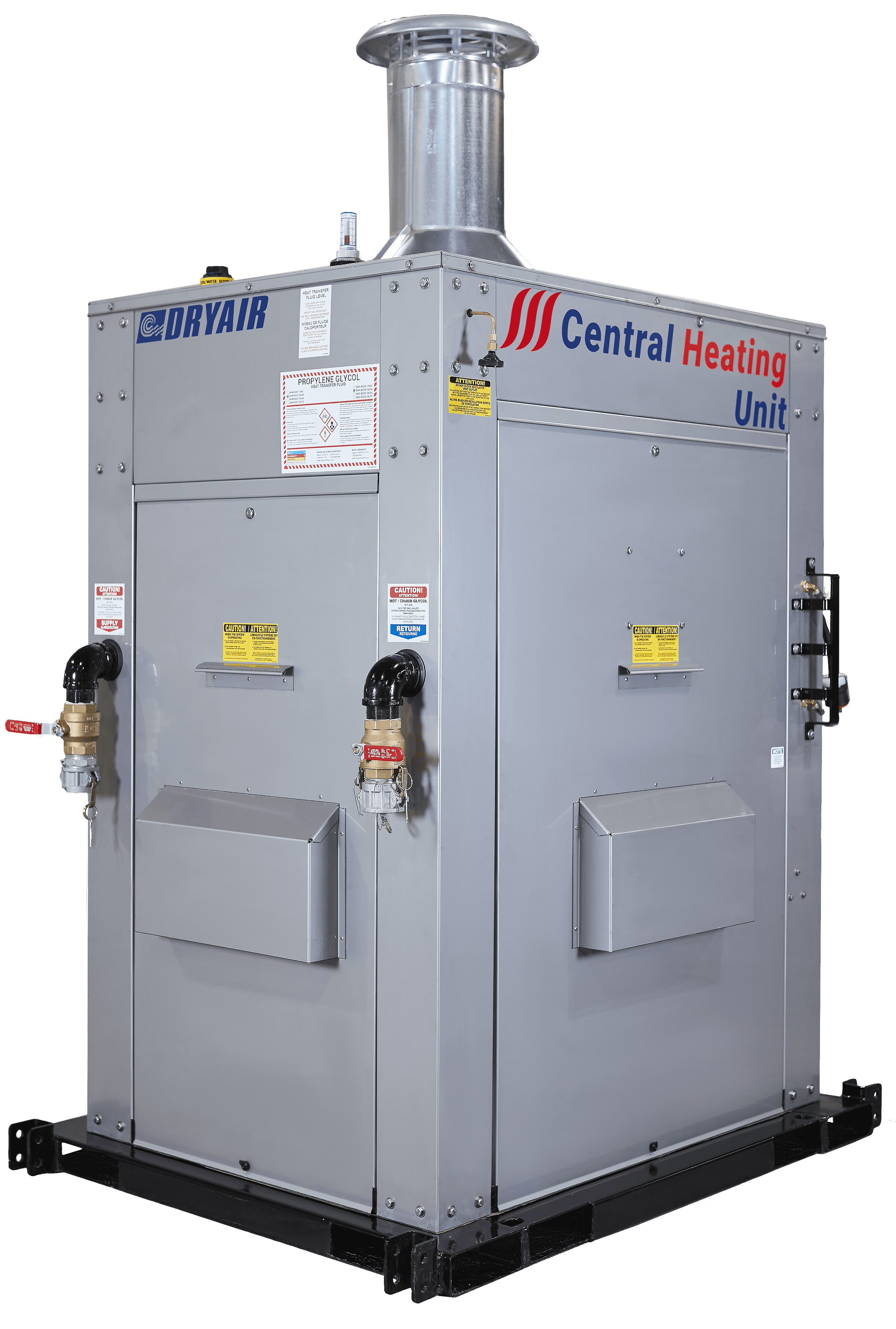

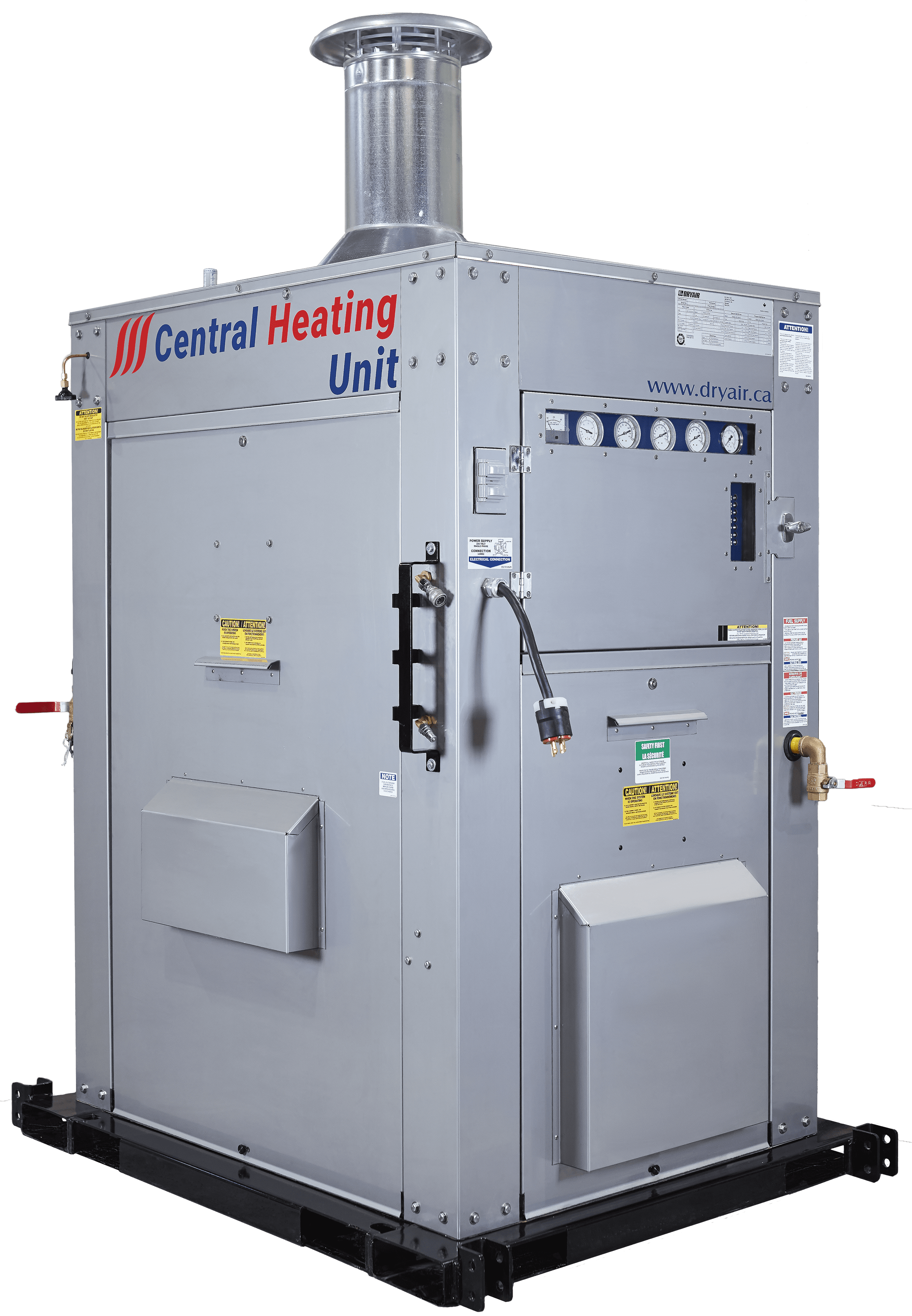

900 CHU Central Heating Unit

- The 900 CHU is available in a diesel version, a gas version which operates on LP or NG and a Tri-fuel version which operates on diesel, LP or NG. Conversion from one fuel source is accomplished with a quick burner change-out.

- Conversion from one fuel source to another can be accomplished in as little as 15 minutes.

- Includes unique “Combustion Environment Control” system which ensures efficient and reliable burner operation in all conditions.

- Compact and portable design for easy positioning on the work site.

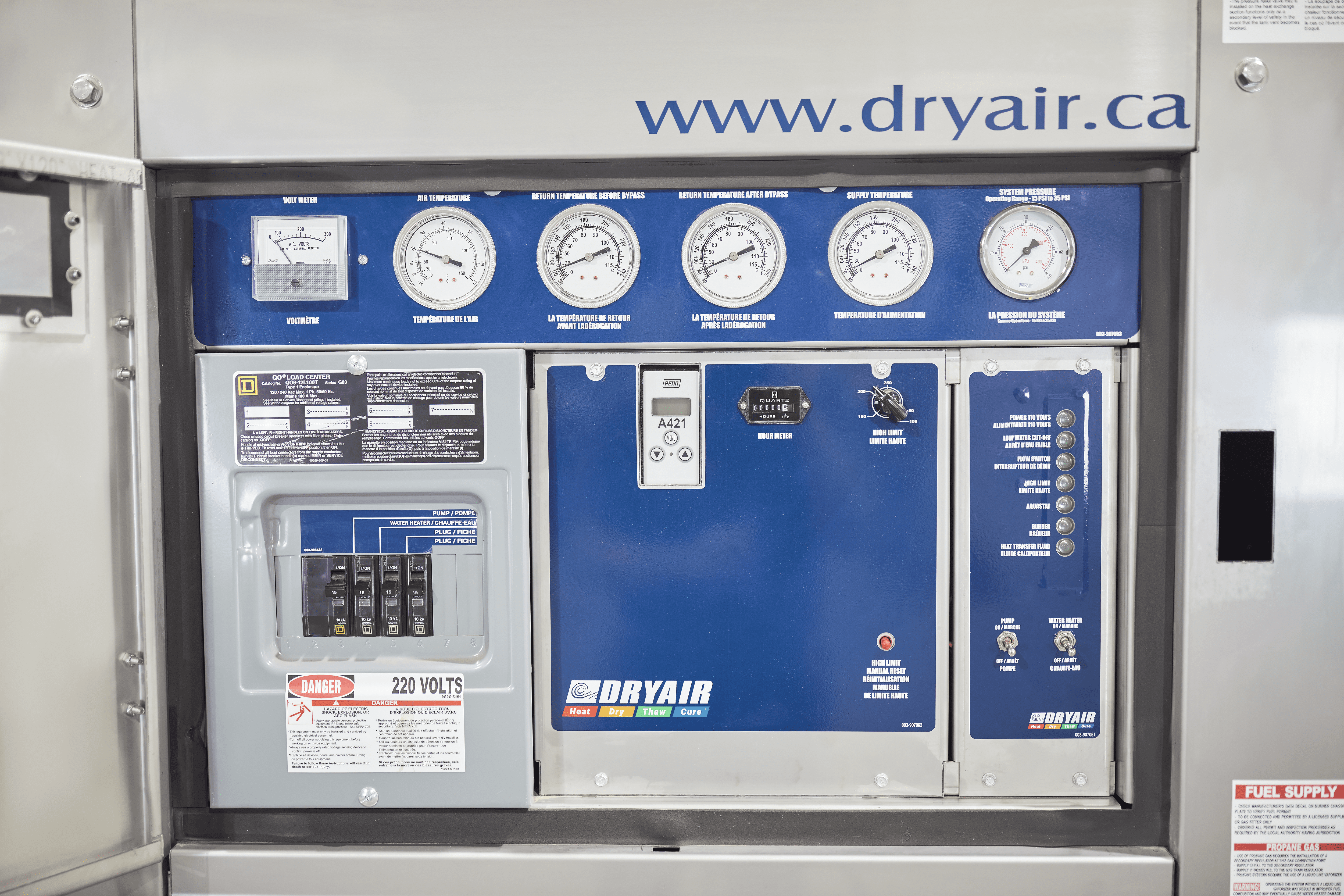

- All system operation is controlled and monitored from the central heating module control panel.

- 8-light system operating feature for easy system troubleshooting.

- Fluid circulation system is low pressure and atmospherically vented. There is no chance of an explosion or line burst due to pressure build-up. No special boiler certification is required to operate the system.

- Quick connect hose couplers, “no-drain” fluid lines and a “rapid air elimination” feature ensure a quick set-up and go operation.

- Conforms to most special job requirements due to its modular nature.

Combine the 900 CHU with DryAir accessories for specialty heating projects, including:

D-CAN 30 Desiccant Dehumidifier: Dry out flooded structures, or control humidity in buildings under construction to speed drying time of paint, mortar, specialty coatings, or drywall compound.

Fan Coils: Efficient heating for construction and renovation projects, provide an evenly heated, fume-free, low humidity environment.

HEFA 250EX Explosion Proof Fan Coil: 250,000 BTU’s of explosion proof space heating for oil & gas sites or industrial/mining applications where there is a risk of combustion from airborne gases or particles in the space.

Plate Heat Exchanger: Temporarily tie in to boiler systems while the permanent water heater is being replaced or down for maintenance.

Hose Reel & Thawing/Curing Hose: Wrap pipelines or fluid vessels to provide freeze protection.