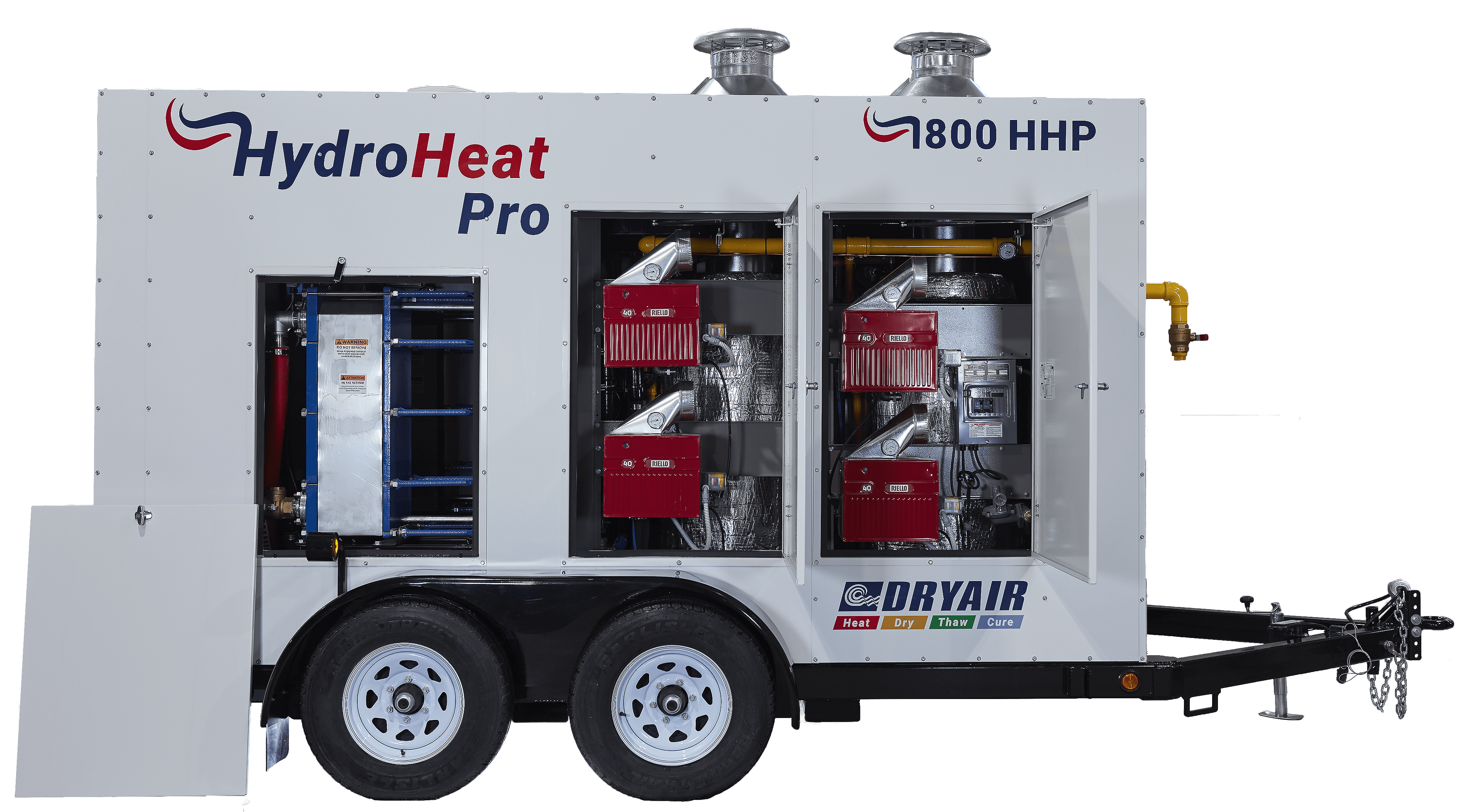

- Tri-Fuel: Diesel, LP or NG

- Input:

- Diesel: 1,792,000 Btu/h

- LP: 1,715,000 Btu/h

- NG: 1,690,000 Btu/h

- Weight: 9,000 lbs

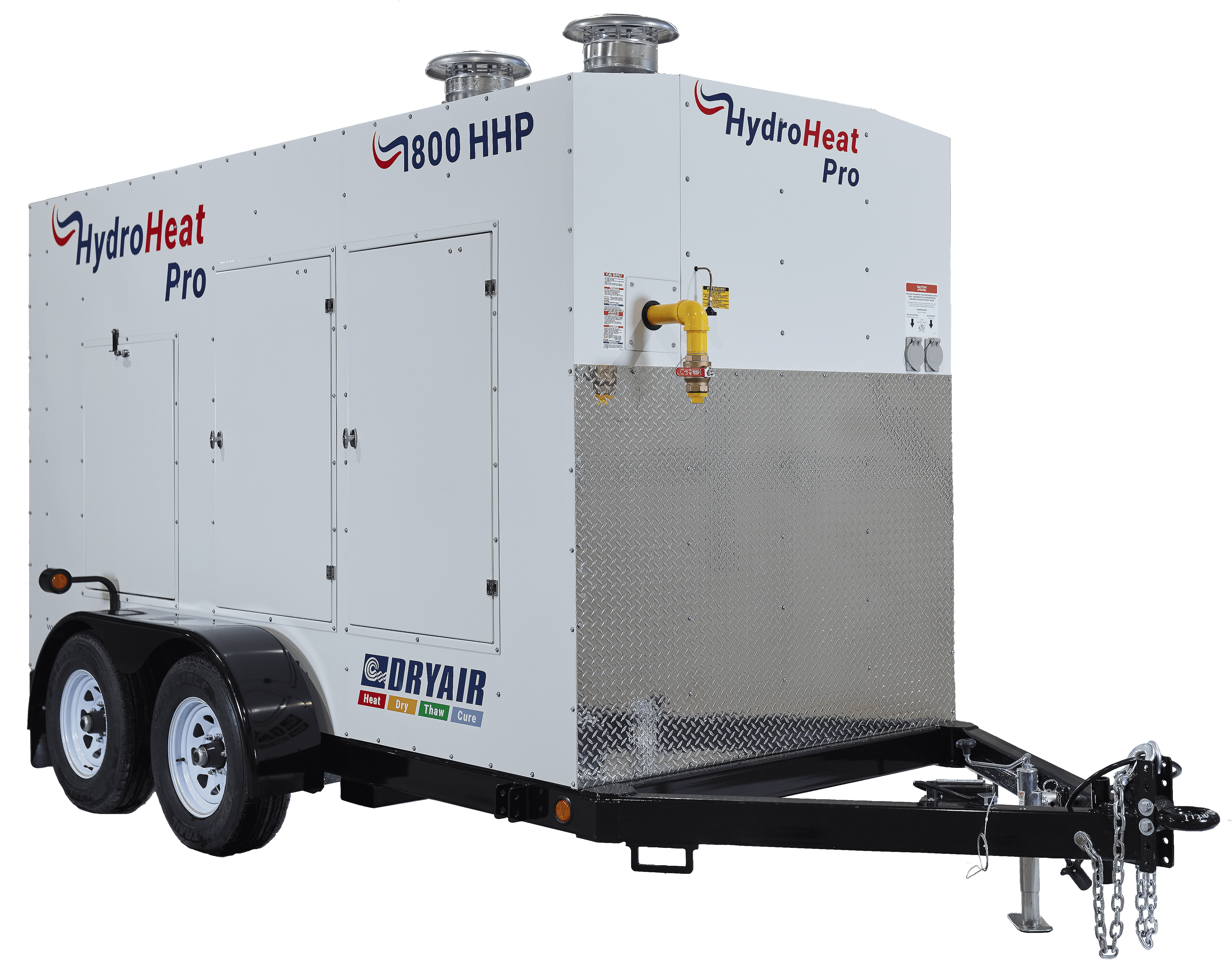

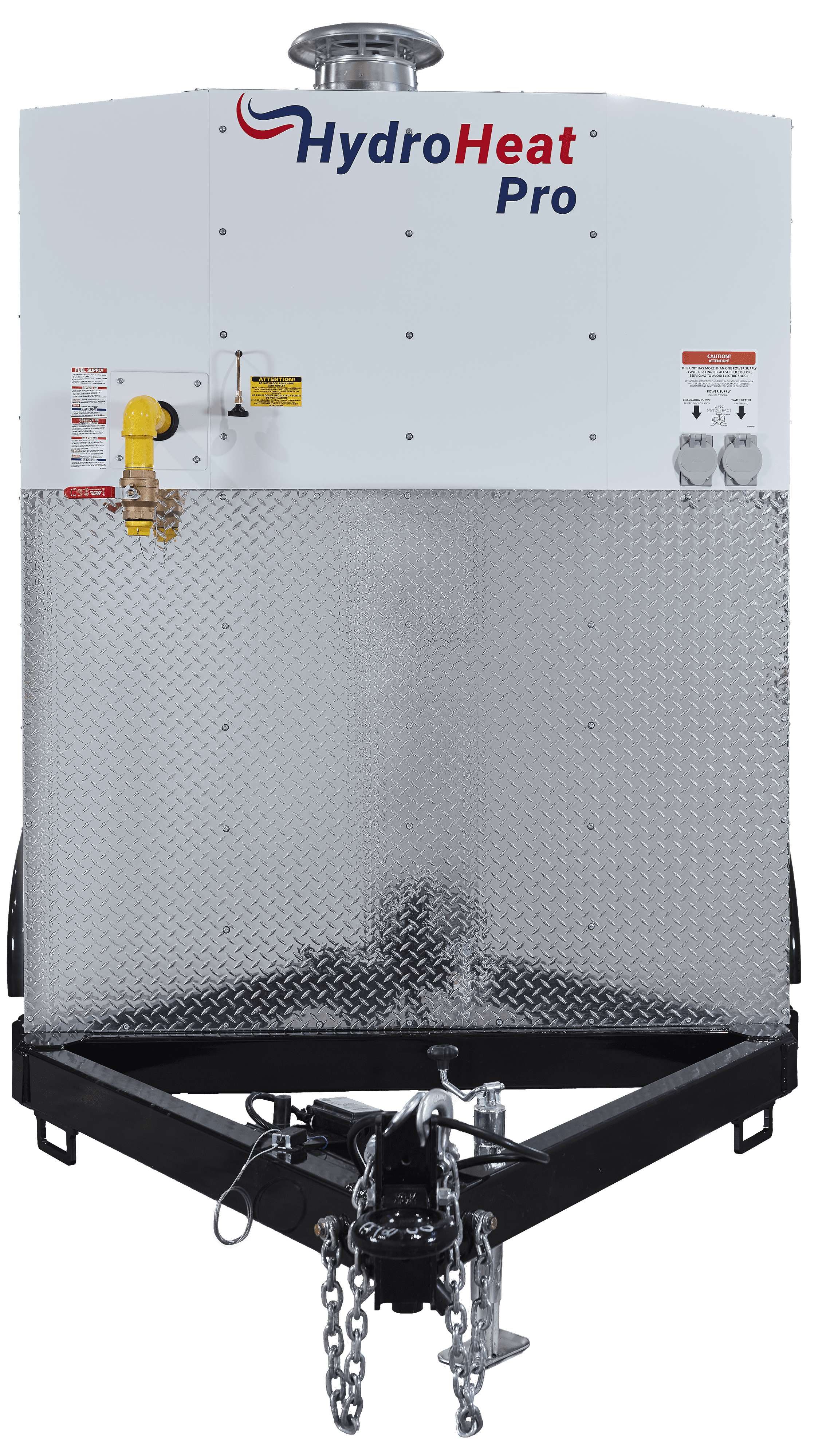

- Dimensions: 212″ l x 93.5″ w x 114″ h

- Optional lift frame available

* Burner change required to switch fuel source.

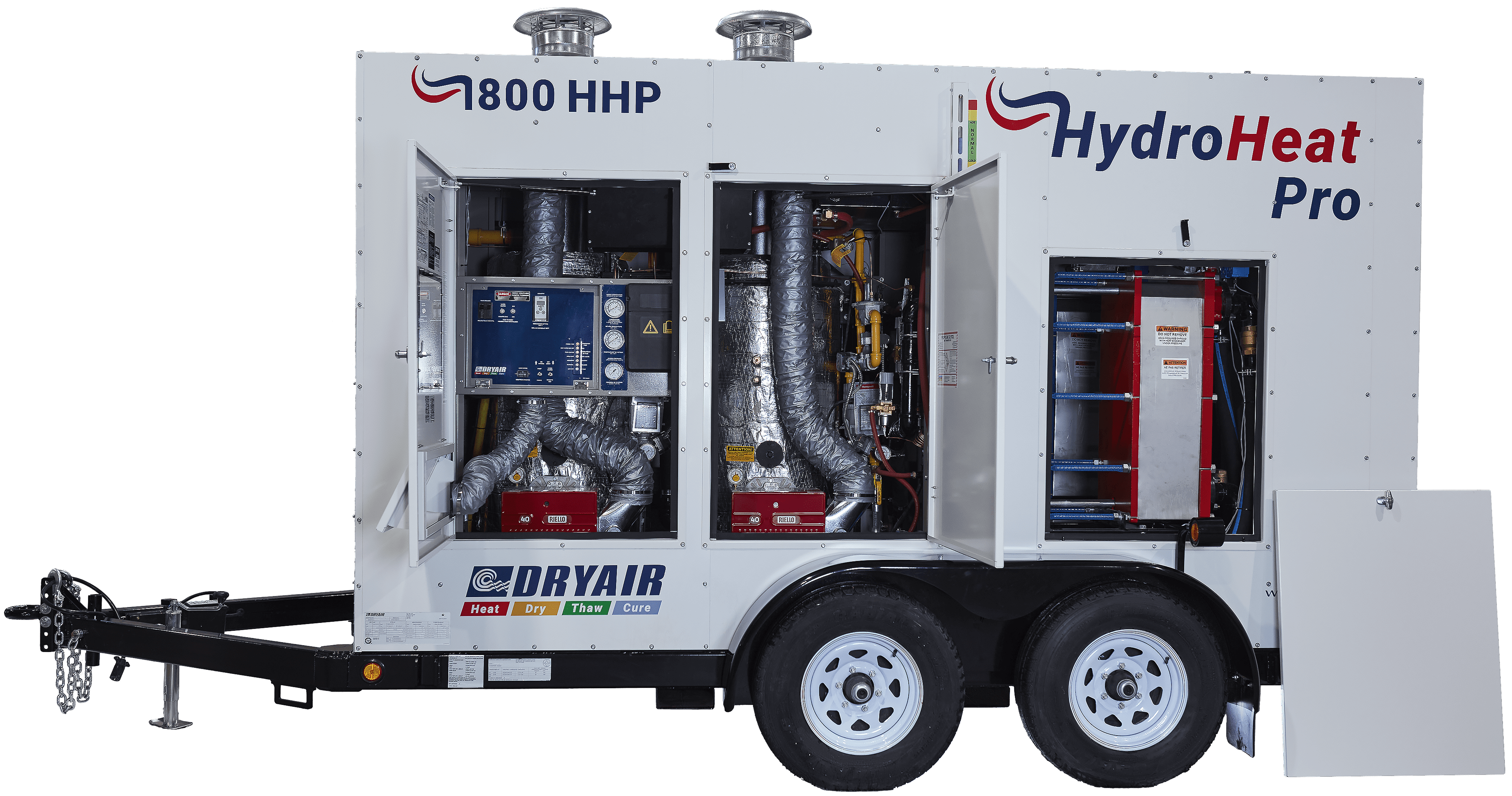

1800 HHP Hydro Heat Pro

The Hydro Heat Pro is targeted to meet the industry’s fluid heating applications, such as boiler tie-ins. The 1.8 million Btu Hydro Heat Pro combines the heating power of the efficient DryAir water heater and two plate heat exchangers into one ready to move, trailer package.

Note: The purpose of a plate heat exchanger is to transfer heat between two fluids, without the fluids mixing.

Features:

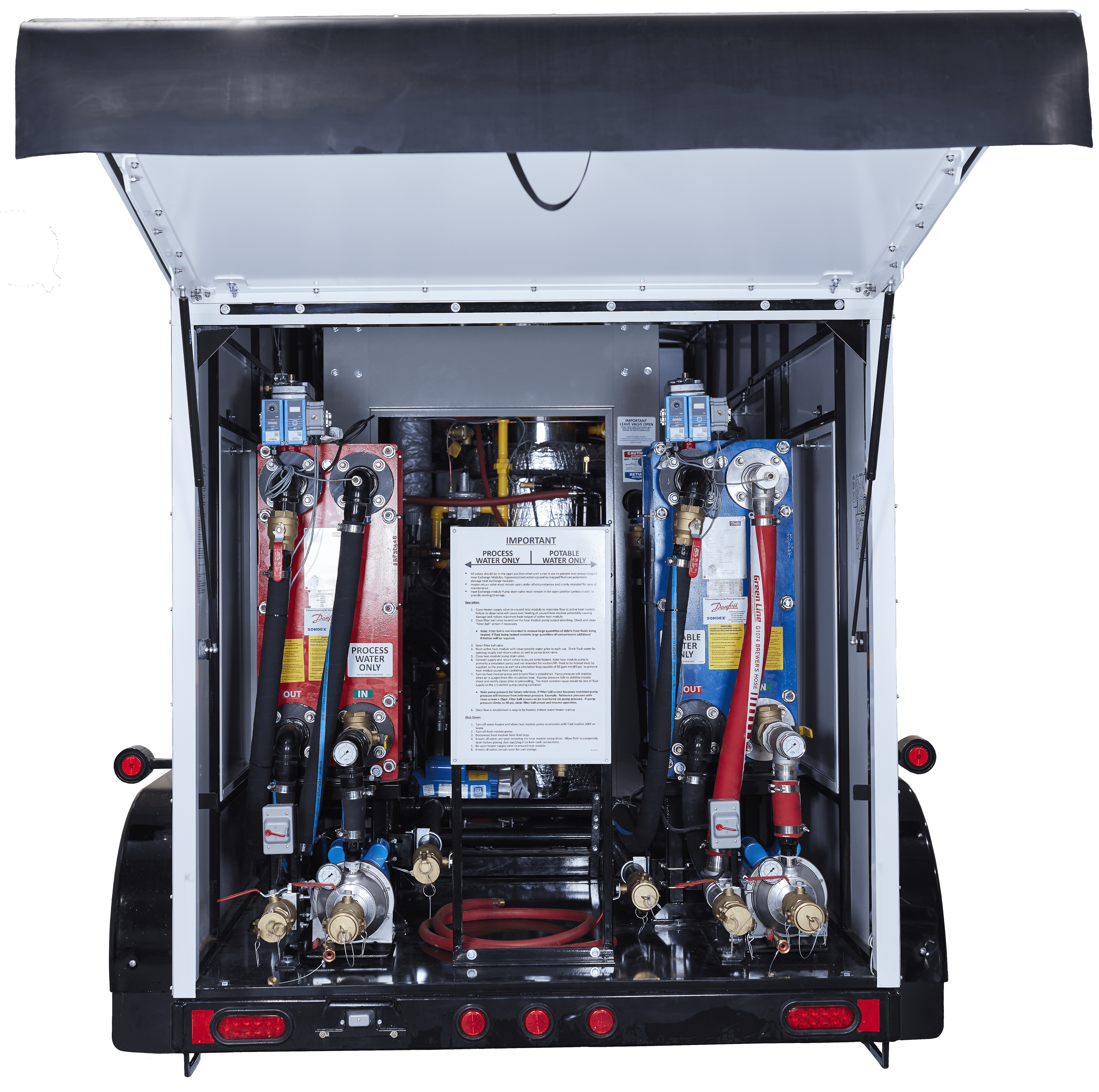

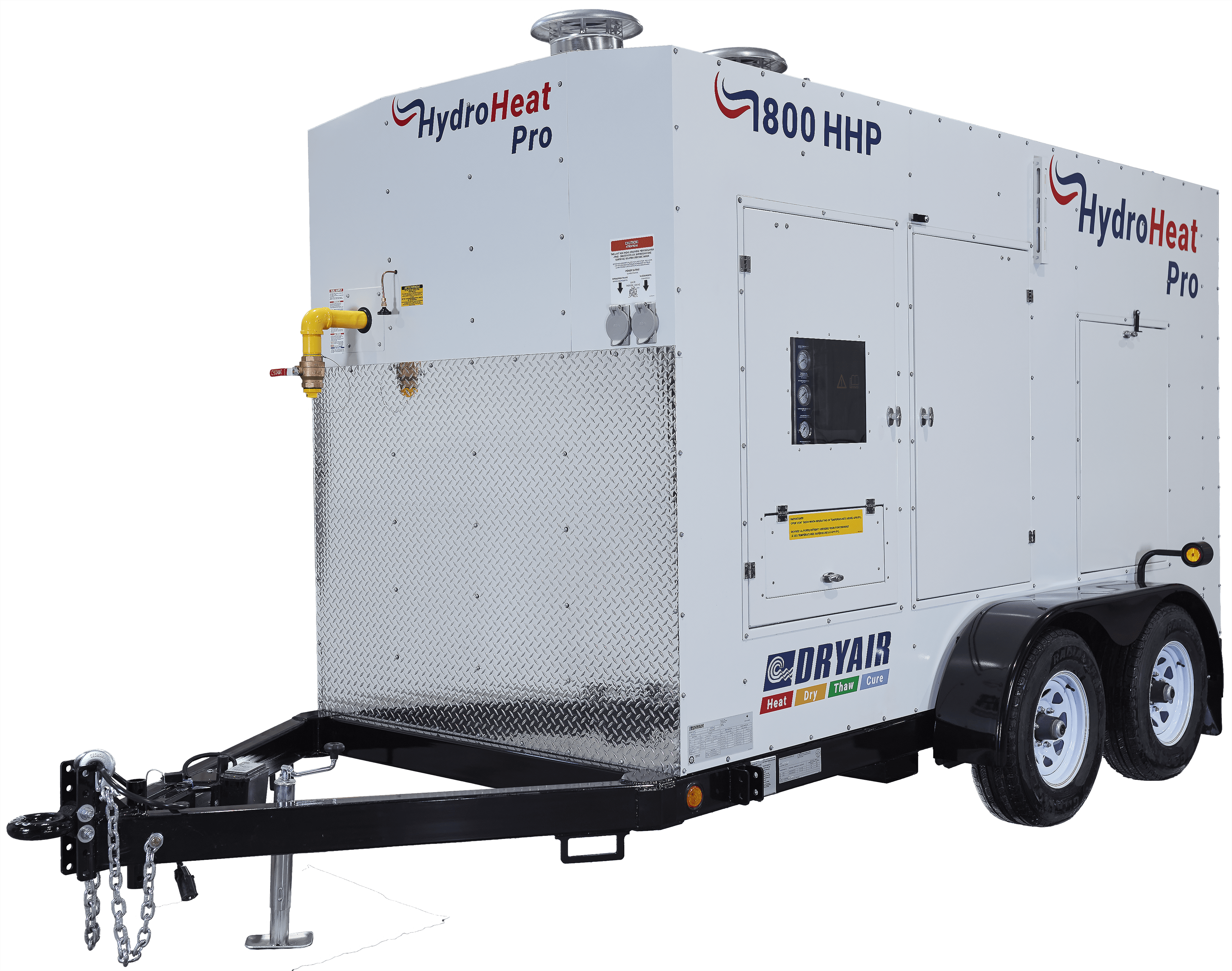

- Two plate heat exchangers, each with 2 million Btu/hr capacity are capable of handling 100% of the output from the water heater. This allows one plate heat exchanger loop to remain dedicated to heating potable water without the risk of contamination.

- The two plate heat exchangers can also heat two different fluids simultaneously.

- Each plate heat exchanger has a pump to circulate the heated fluid to its respective output loop.

- Tri-fuel capable (diesel, natural gas and propane). Switch fuels with a quick burner change-out.

- Convenient designated storage is provided for the burners that are not in use.

- The 1800 HHP starts and operates efficiently all the way down to – 40°F, thanks to the innovative DryAir Combustion Environment Control (CEC) system.

Specific applications:

- Acting as a boiler tie-in, to heat and circulate a building’s heating fluid for potable hot water and building heat.

- Heating and circulating potable hot water in a building complex, bypassing the building’s boiler/water heating system.

- Heating and circulating water for washing facilities at large multiple day events and gatherings.

- The heating and circulating of water for processing plants, mining and oil field projects.

- For larger jobs, where one DryAir heating unit is not adequate, the Hydro Heat Pro’s plate heat exchanger can be connected in series to boost output.