- Fuel: Diesel

- Input: 212,800 Btu/h

- Fuel Capacity: 80 US gal

- On-board Hose: 3/4″ 600 ft (std), 1,200 ft*

- Heat Area: 6,000 ft²

- Thaw Area: 1,800 ft² (std), 3,600 ft²*

- Cure Area: 2,400 ft² (std), 7,200 ft²*

- Weight: 4,315 lbs

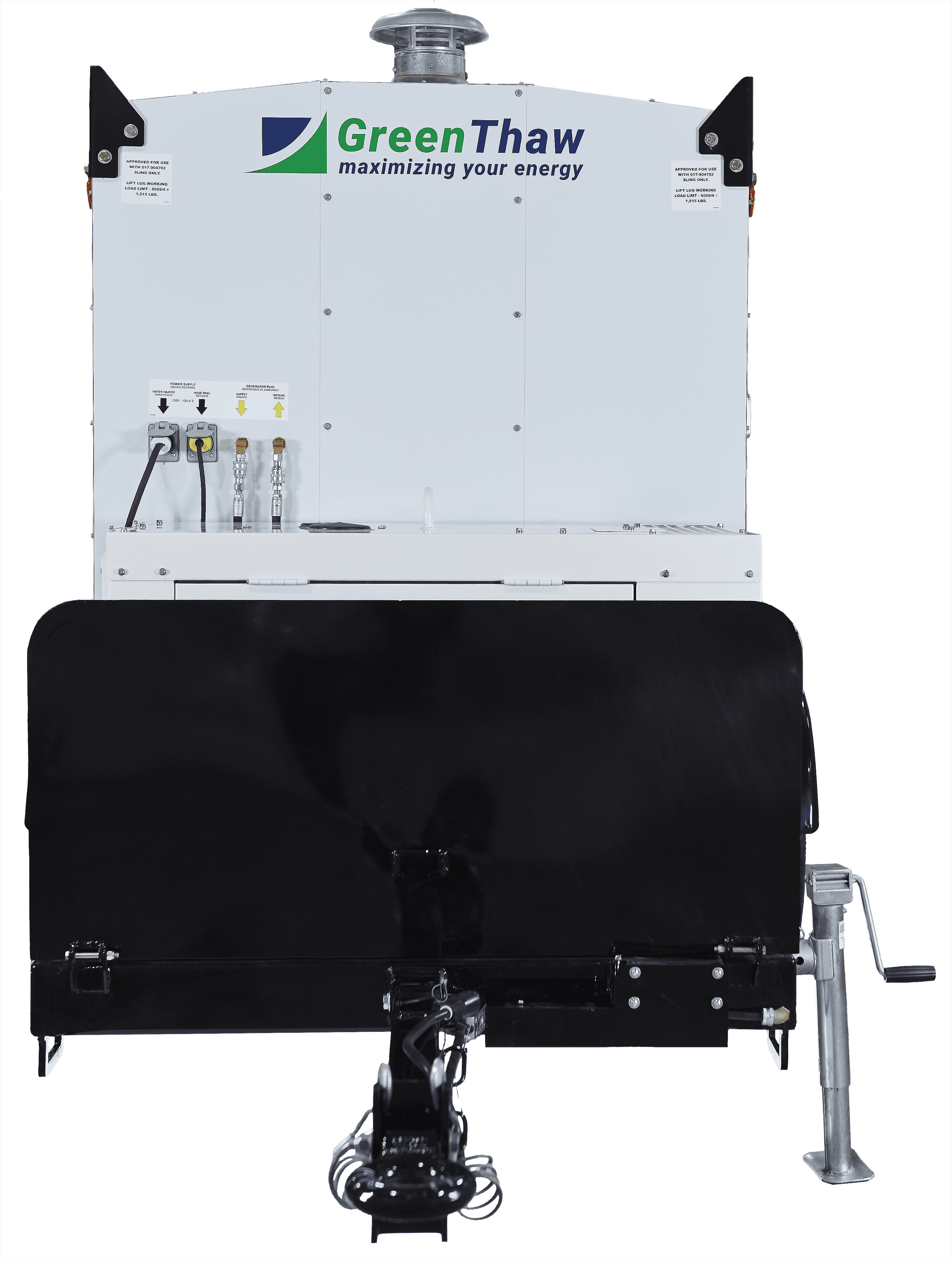

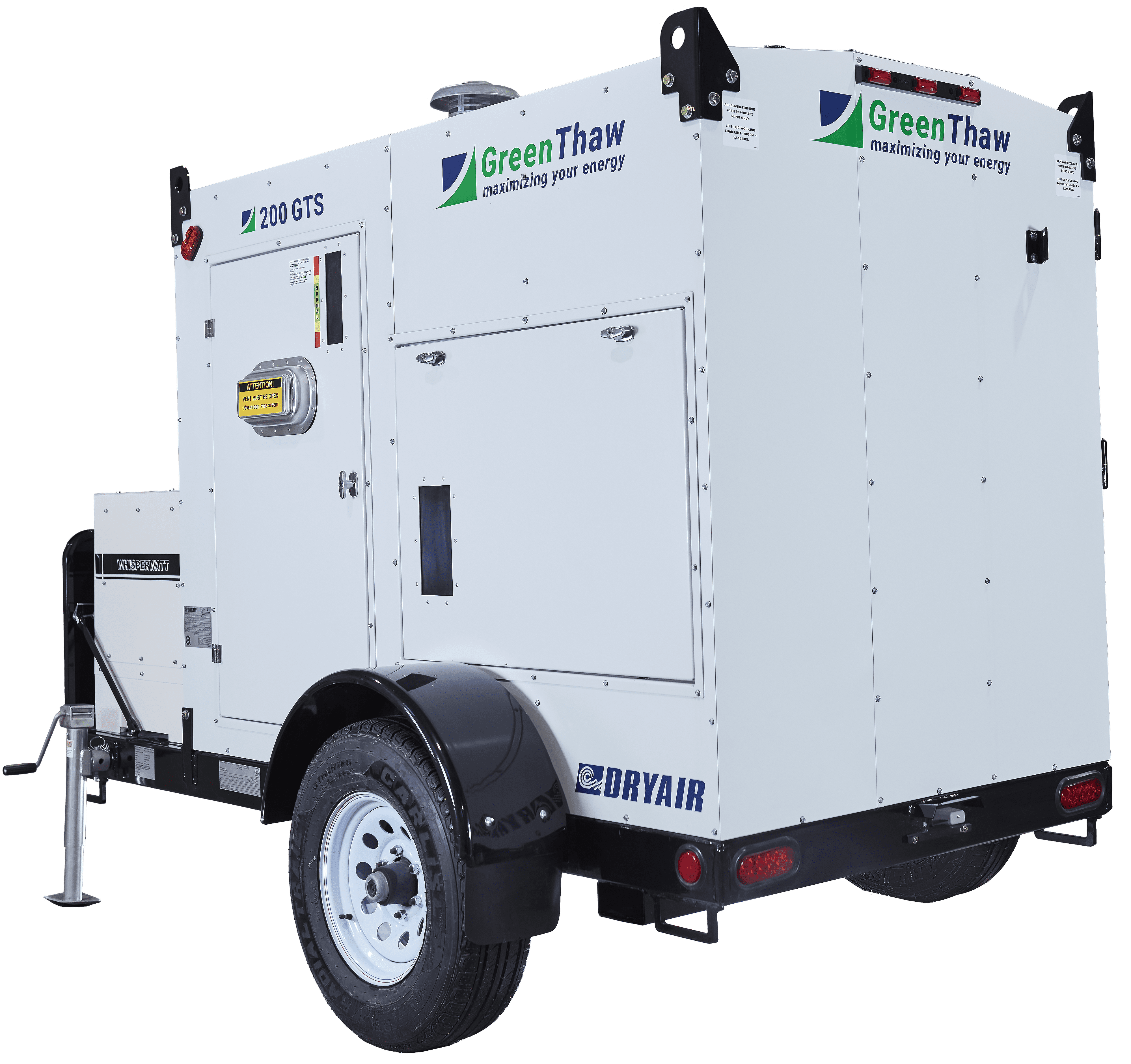

- Dimensions: 122/166″ l x 76″ w x 92″ h

(Length with tow pole up/down) - Integrated lift frame

* Additional hose and accessories are used to reach the maximum thawing and curing capabilities listed above.

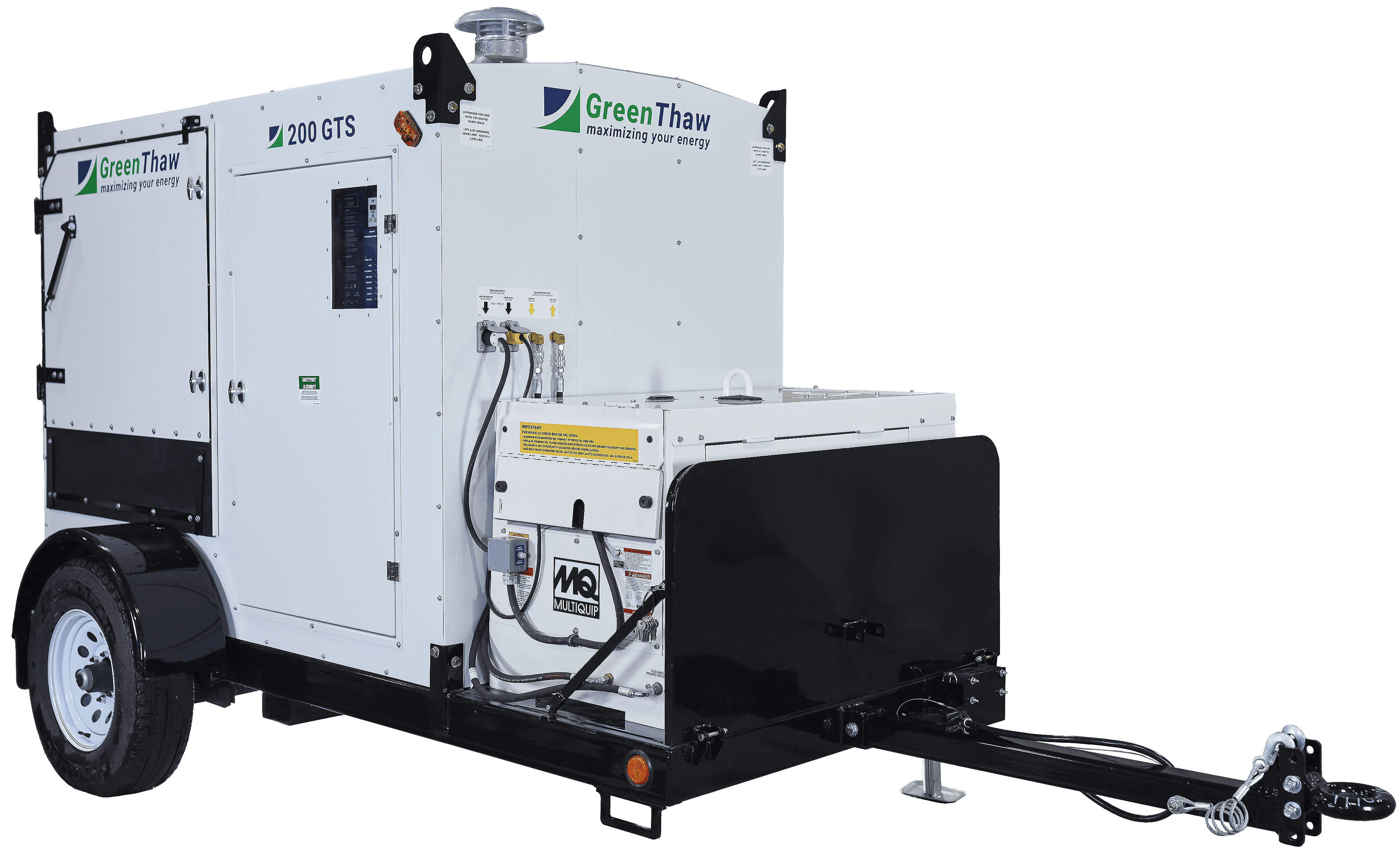

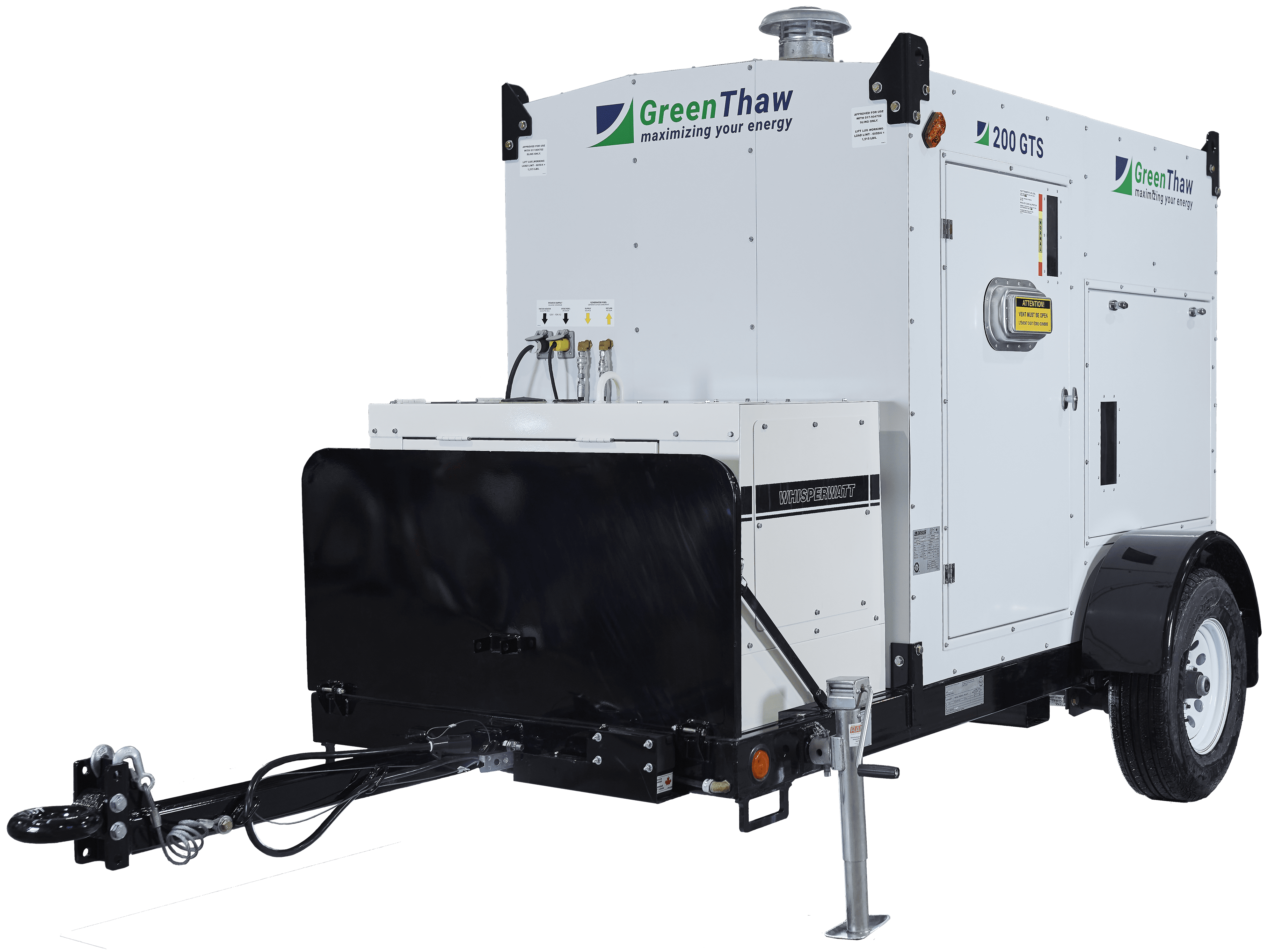

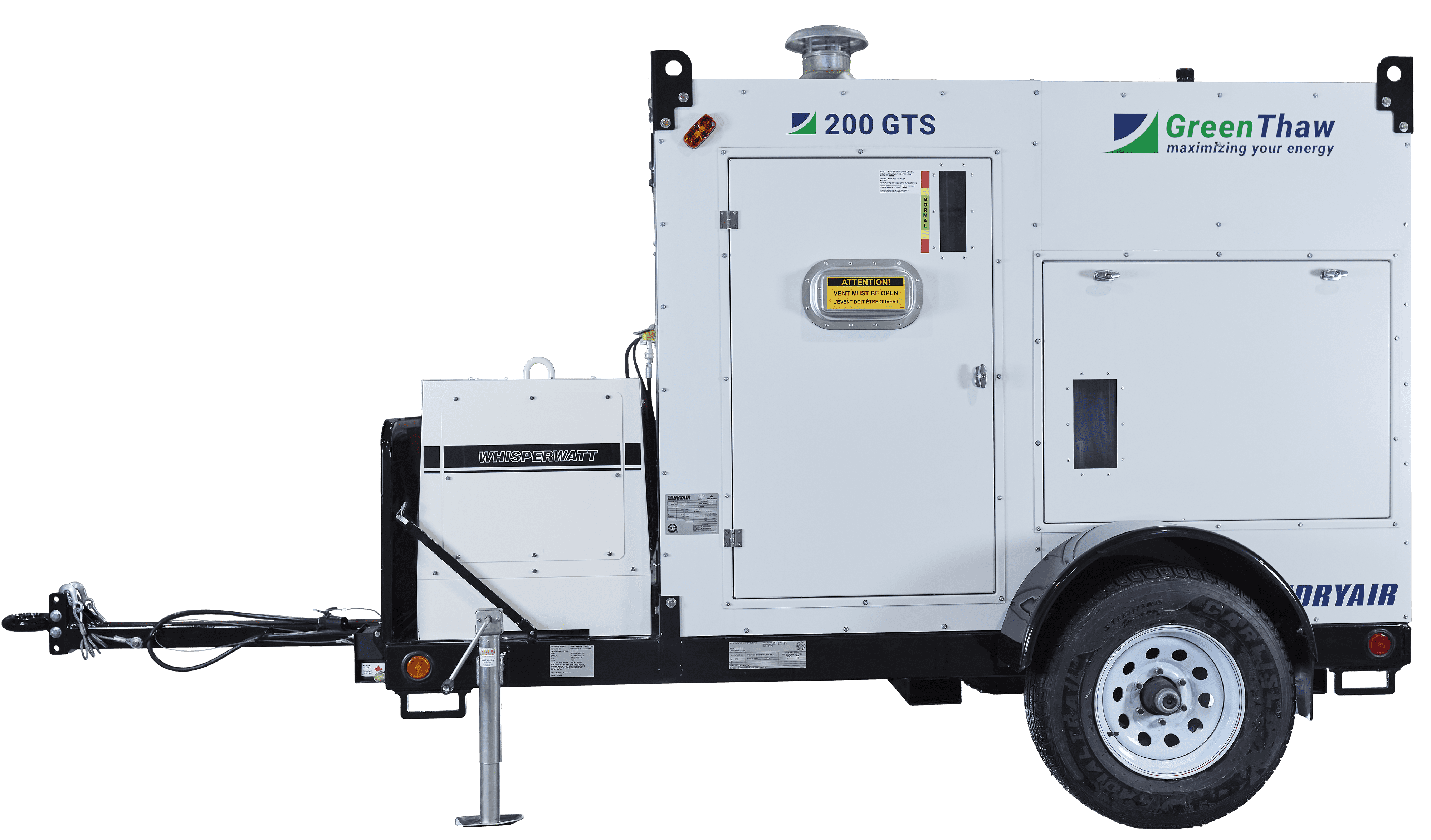

200 GTS GreenThaw™ System

The 200 GTS features class leading Btus in compact size, allowing it to go where larger ground thaw units cannot. With the tow pole in the upright position, the unit is only 122″ long. Integrated lifting hooks and fork pockets assist in placing the 200 GTS into tight spaces.

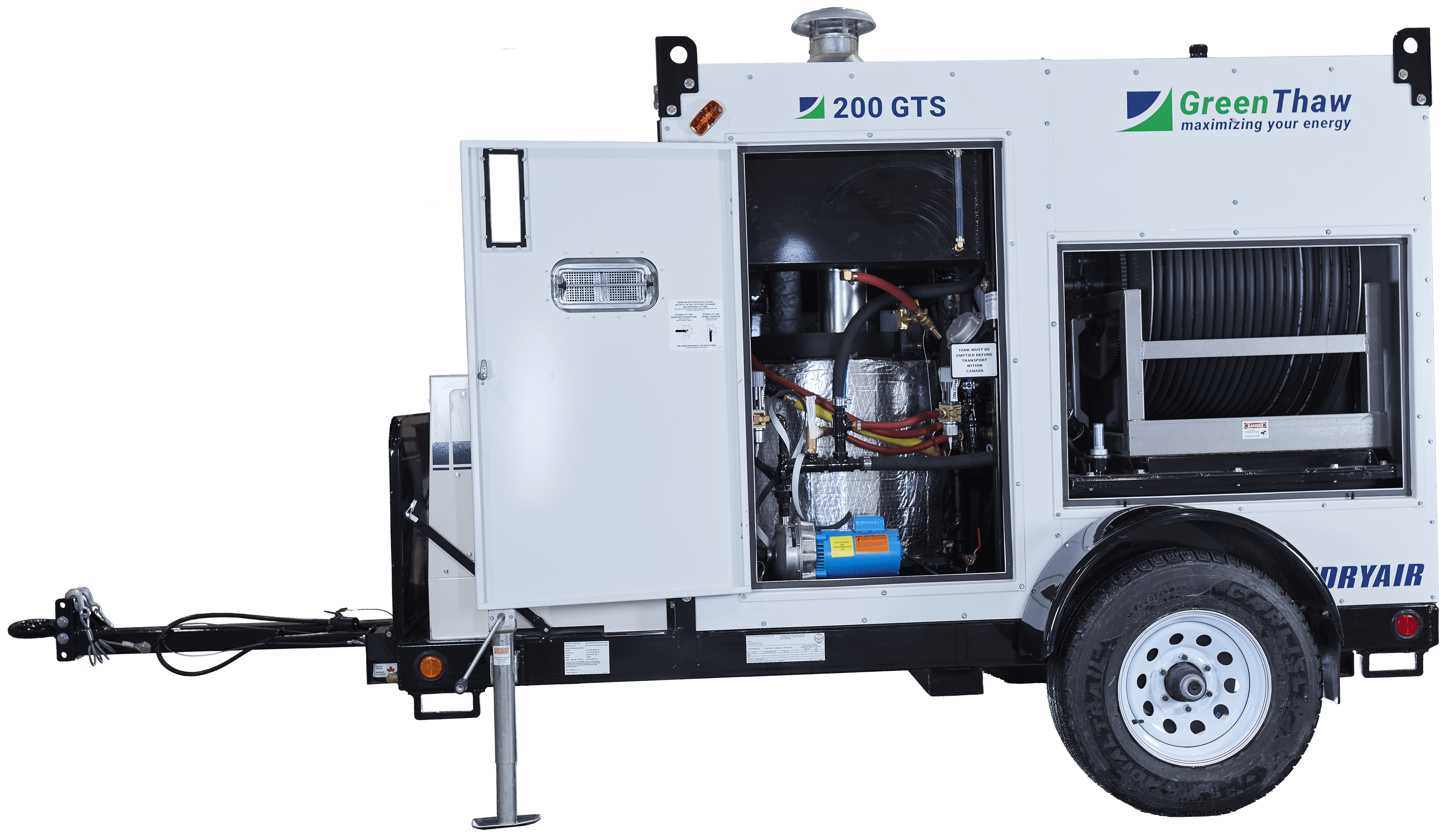

The 200 GTS is equipped with 1,200 ft of 3/4″ hose. With 40% greater surface area in contact with the ground or concrete, the 200 GTS delivers faster results. The hose can be deployed in one long 1,200′ loop or split into 2 – 600′ loops, allowing greater flexibility in hose placement.

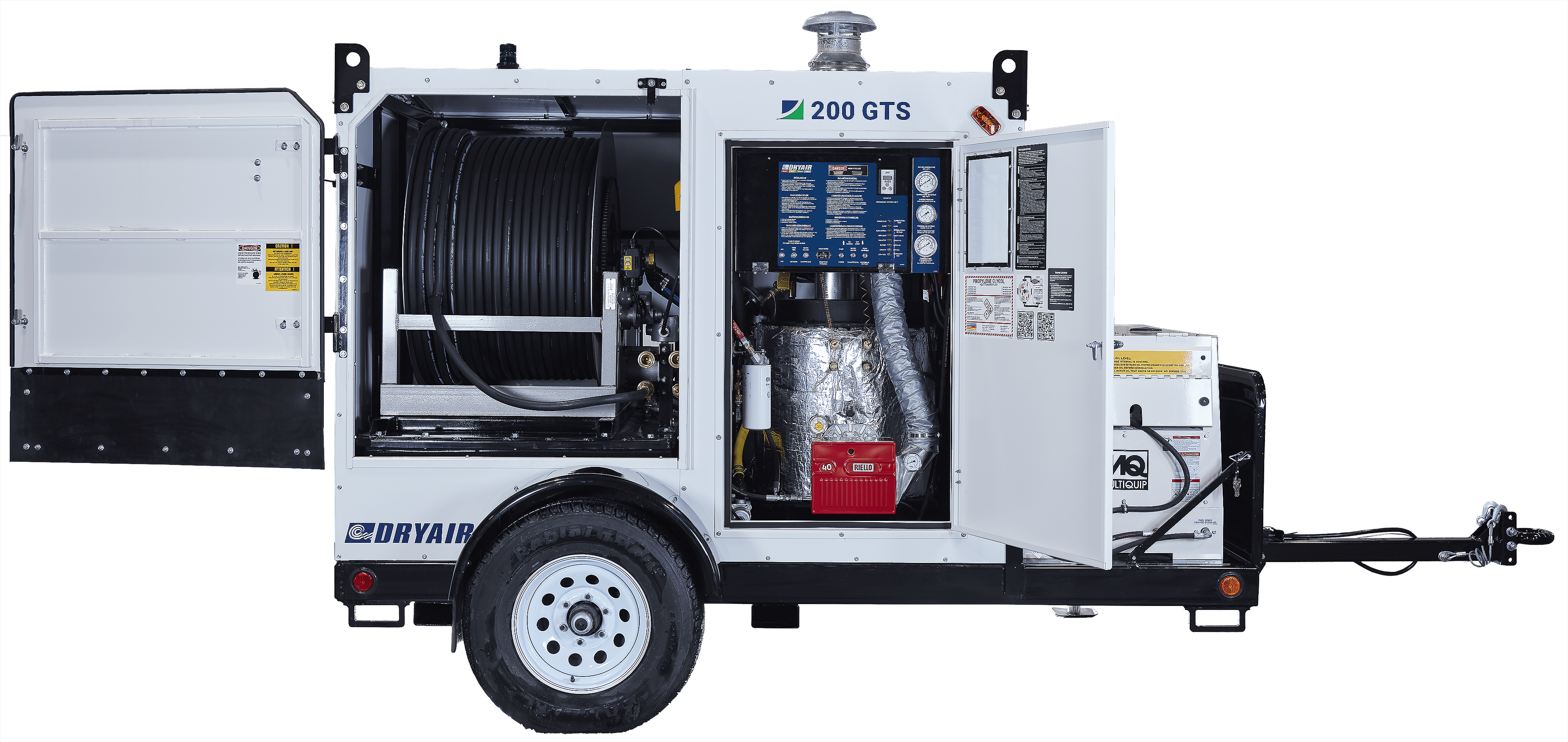

Continuing in our tradition of providing easy access to all service points, the 200 GTS features large doors on both sides of the unit.

DryAir’s innovative CEC (combustion environment control) system, preheats the combustion air and fuel to provide the burner with an ideal combustion environment in the widest range of ambient conditions. Wide outside temperature swings will not affect the DryAir’s 200 GTS GreenThaw–it hums right along!

The patented GreenThaw Flow Reverser, made famous in our larger models, is also available in the 200 GTS. Set the timer to the recommended schedule for thawing or curing to ensure every square foot receives adequate heat for the job.

No other ground thaw system can deliver the uniform heat of the DryAir GreenThaw.

Combine the 200 GTS with DryAir accessories for specialty heating projects, including:

Fan Coils: Efficient heating for construction and renovation projects, provide an evenly heated, fume-free, low humidity environment.

HEFA 250EX Explosion Proof Fan Coil: 250,000 BTU’s of explosion proof space heating for oil & gas sites or industrial/mining applications where there is a risk of combustion from airborne gases or particles in the space.

Plate Heat Exchanger: Temporarily tie in to boiler systems while the permanent water heater is being replaced or down for maintenance.