- Fuel: Diesel

- Input: 348,000 Btu/h

- Fuel Capacity: 150 US gal

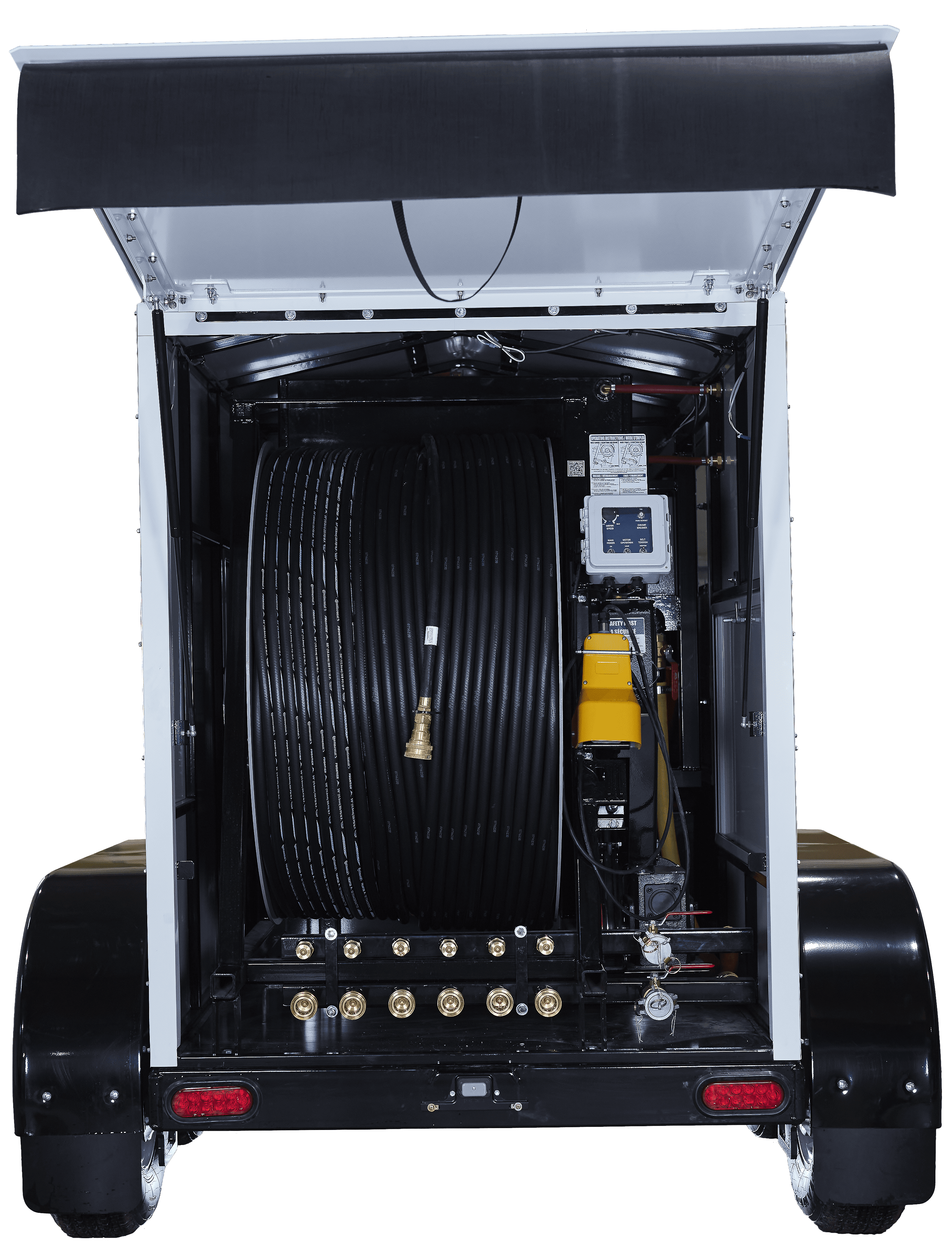

- On-board Hose: 5/8″ 3,000 ft

- Heat Area: 11,000 ft²

- Thaw Area: 4,500 ft² (std), 6,000 ft²*

- Cure Area: 6,000 ft² (std), 14,000 ft²*

- Weight: 5,950 lbs

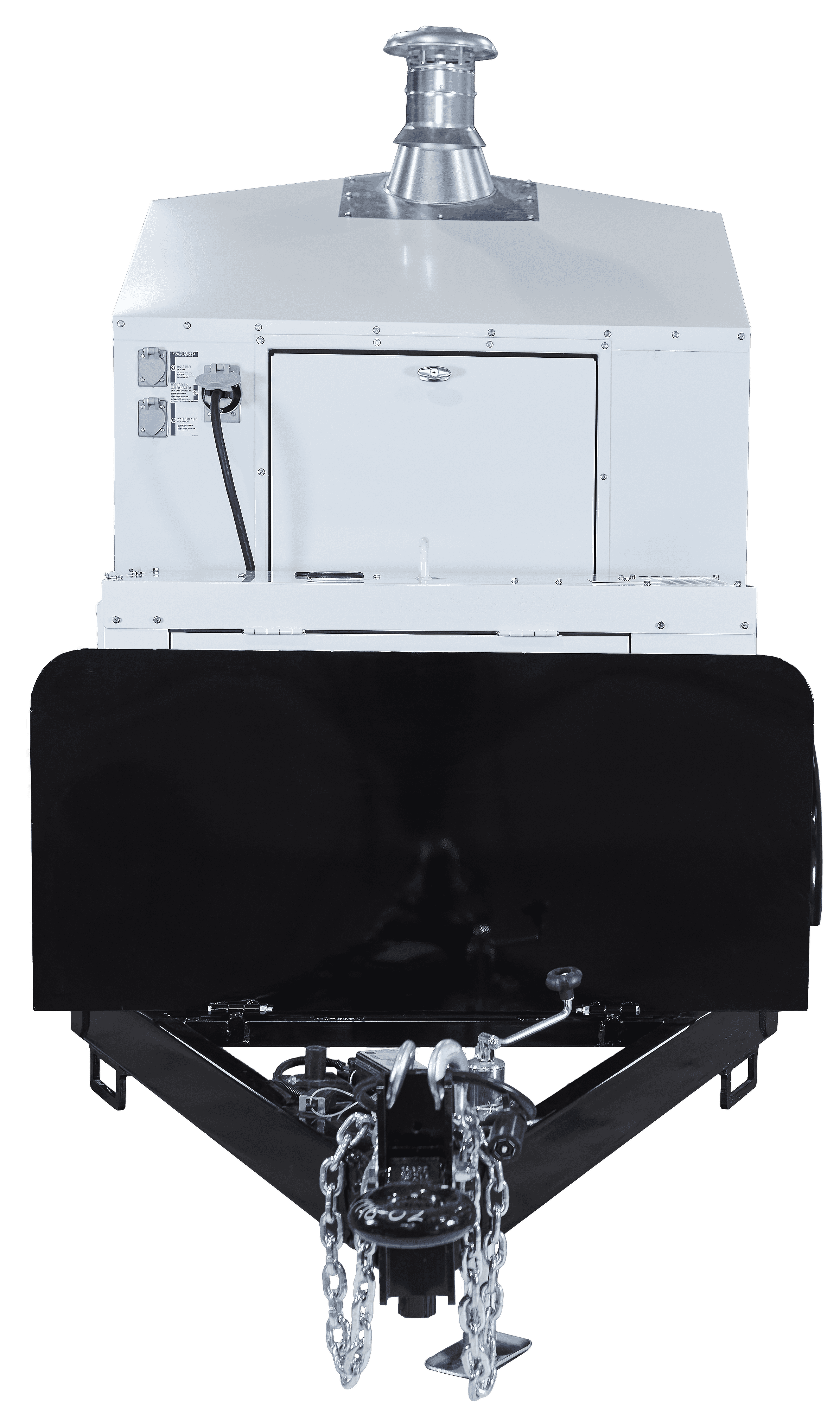

- Dimensions: 188″ l x 76″ w x 98″ h

- Optional lift frame available

* Additional hose and accessories are used to reach the maximum thawing and curing capabilities listed above.

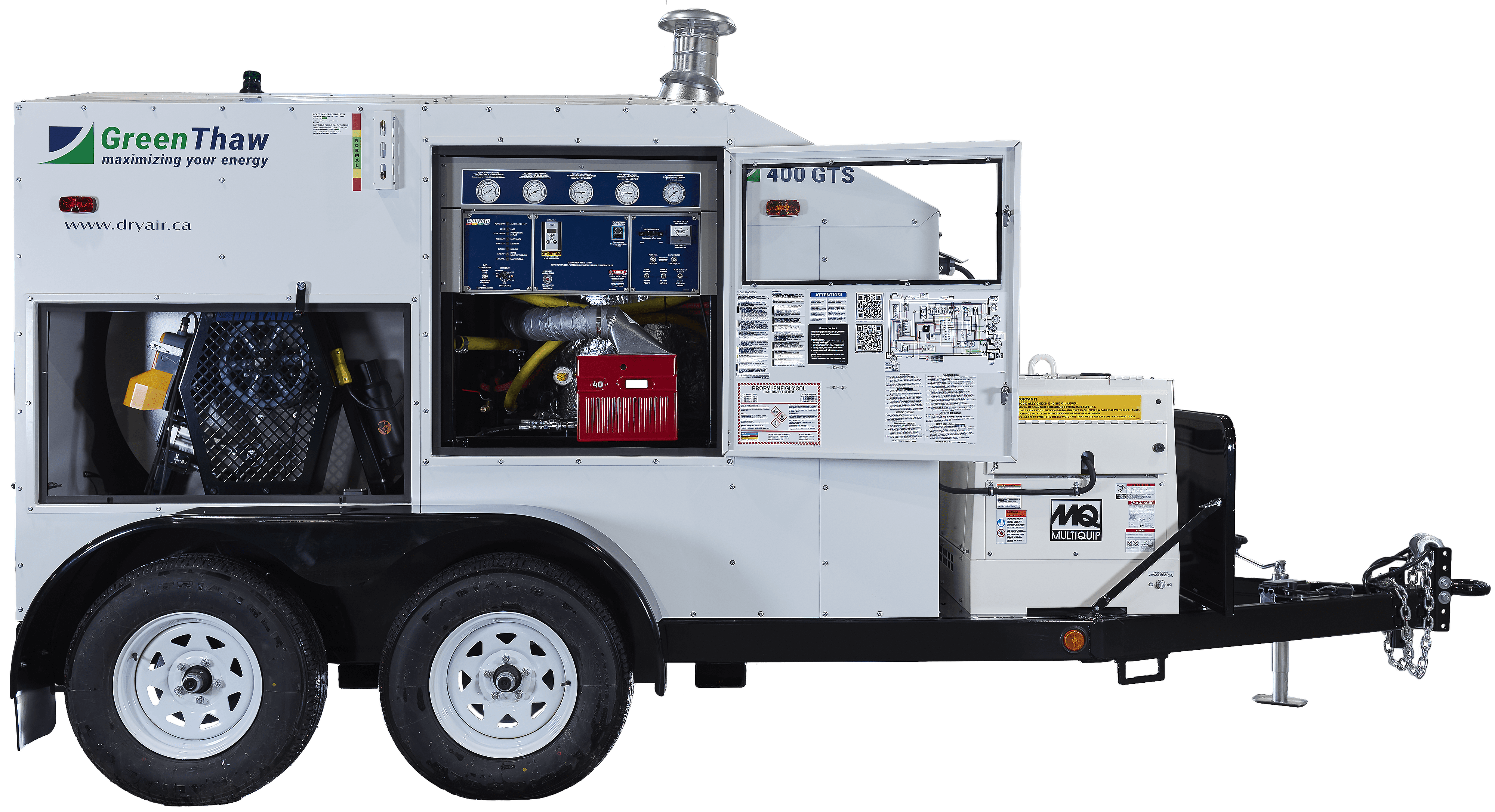

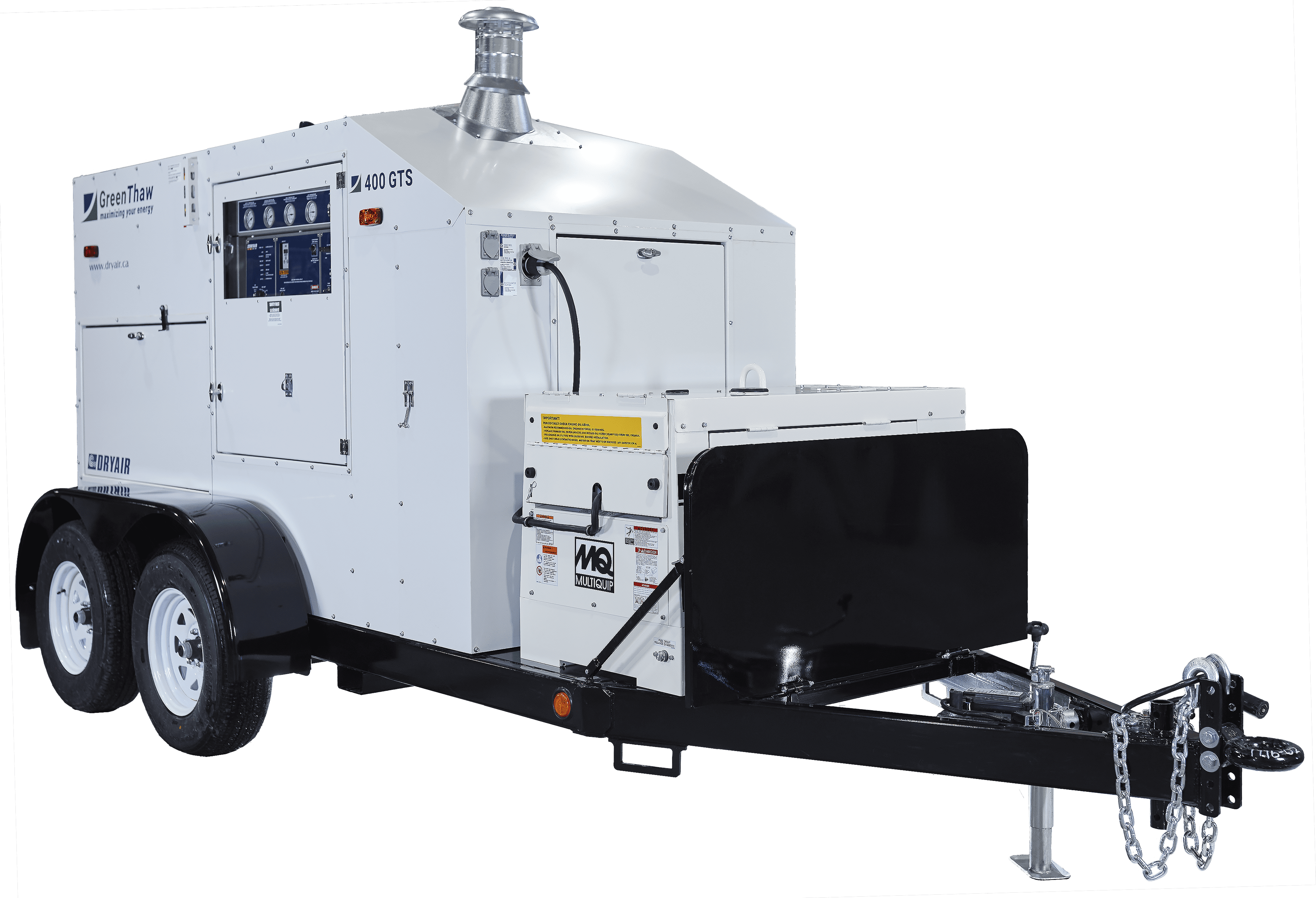

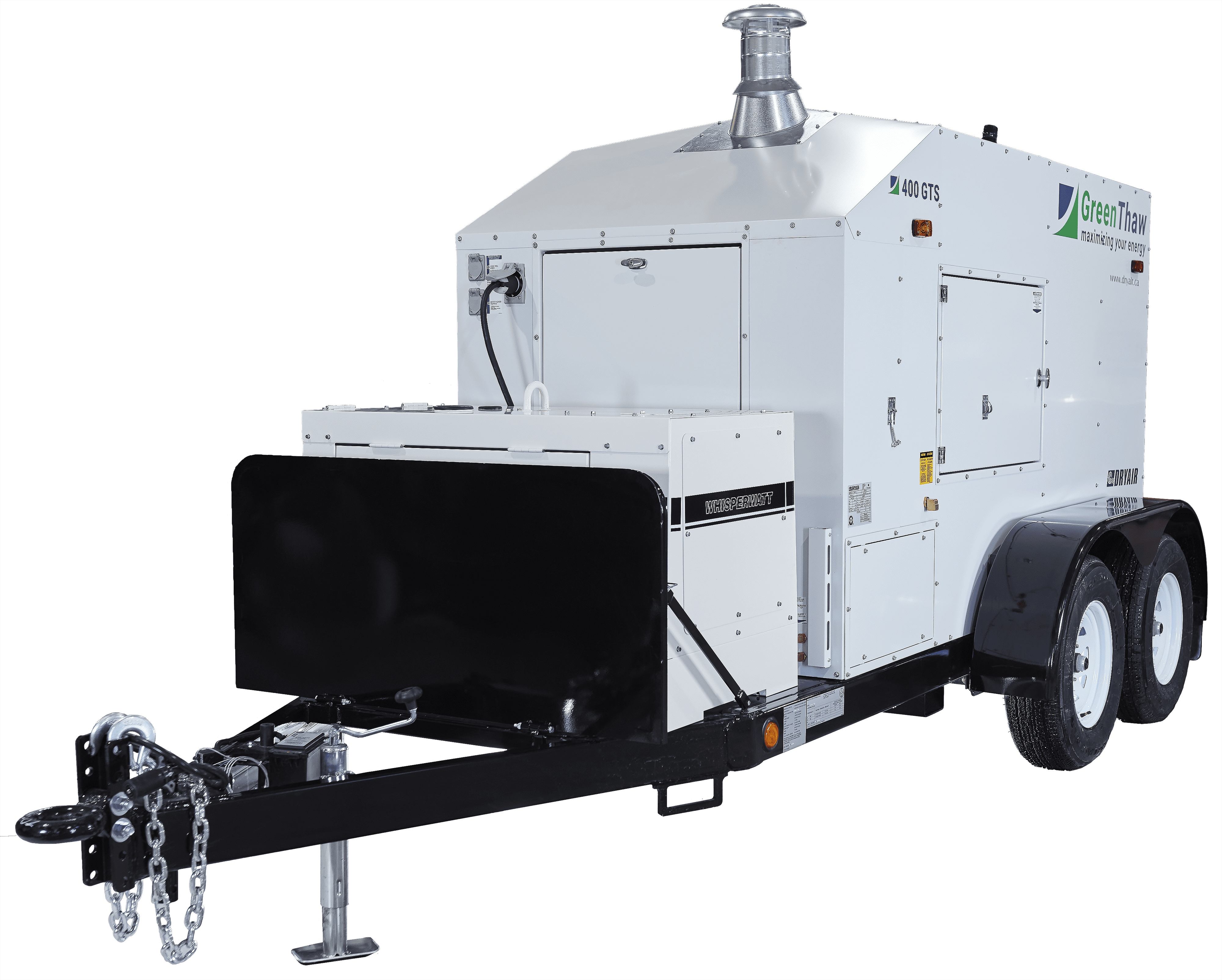

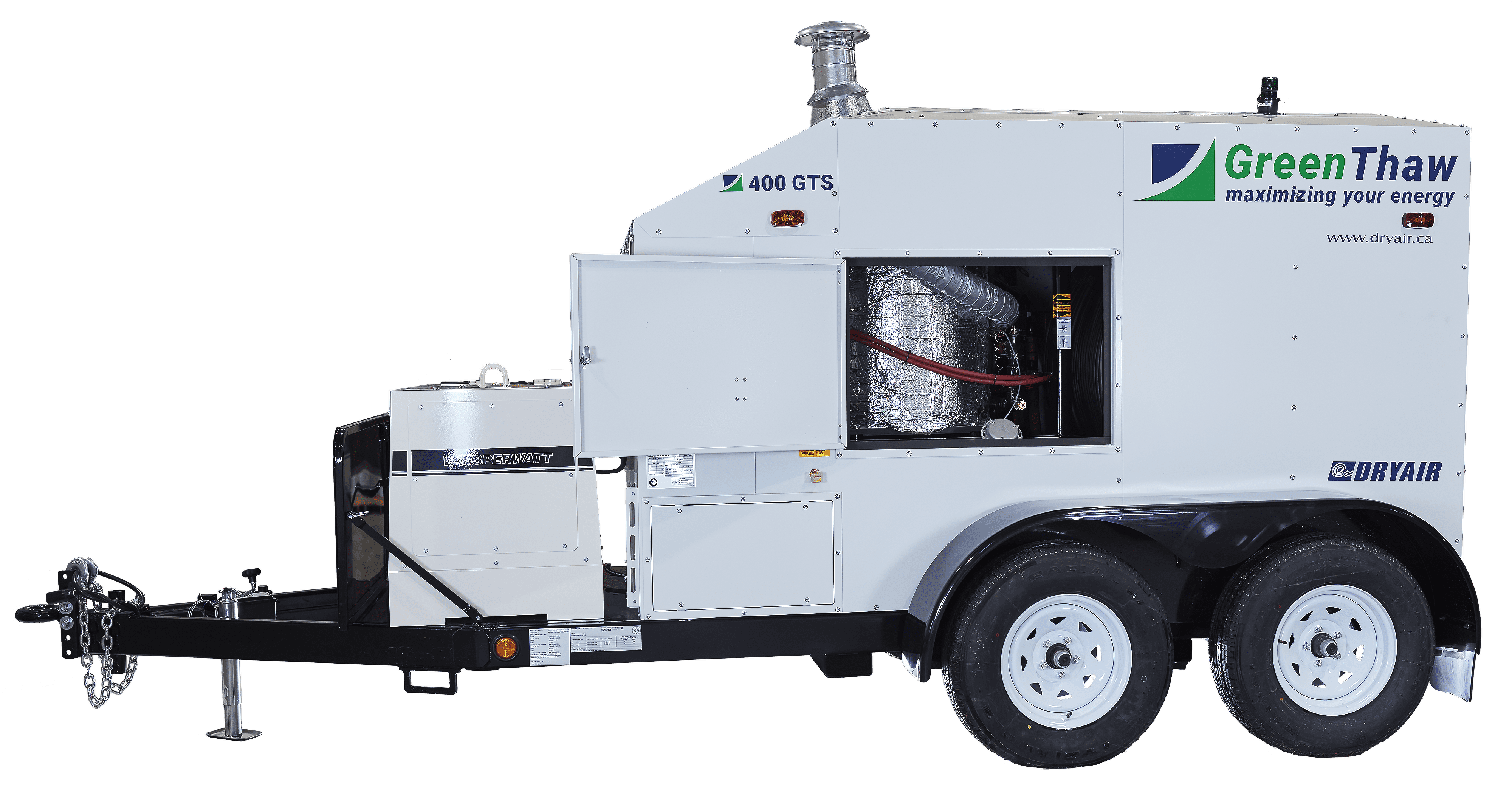

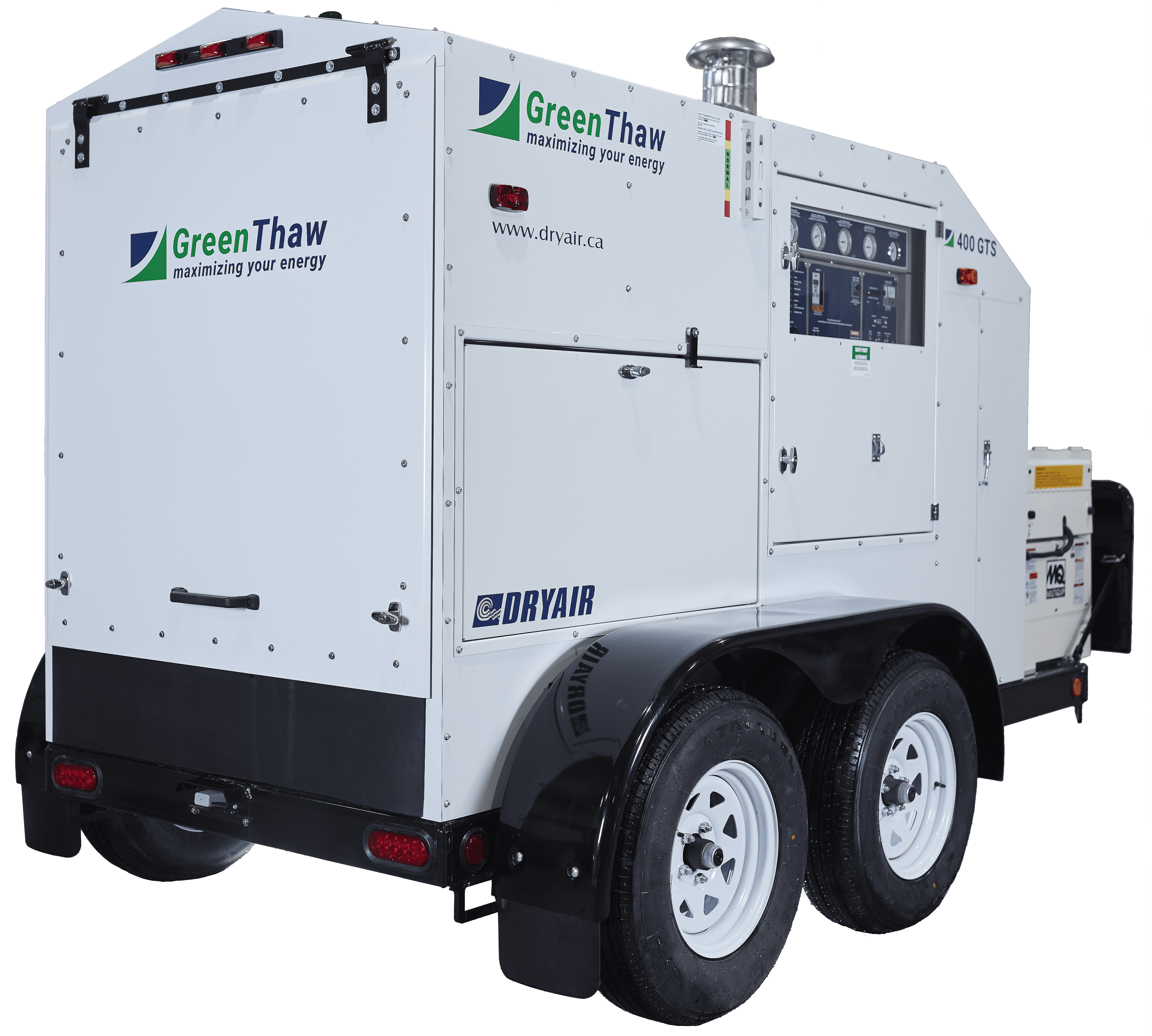

400 GTS GreenThaw™ System

The DryAir Greenthaw system gives you almost perfect control over the temperature of your concrete pour. By adjusting the ‘flow reverser controller’ to the recommended schedule, every square foot of your concrete pour will receive the same amount of heat. This means a uniform curing pattern and less likelihood of problems caused by uneven curing. DryAir’s ‘even heat’ approach to curing will also reduce the risk of freezing.

The large 348,000 Btu heater provides you with Btu’s ample maximizing heat exchanger capabilities even in the harshest conditions.

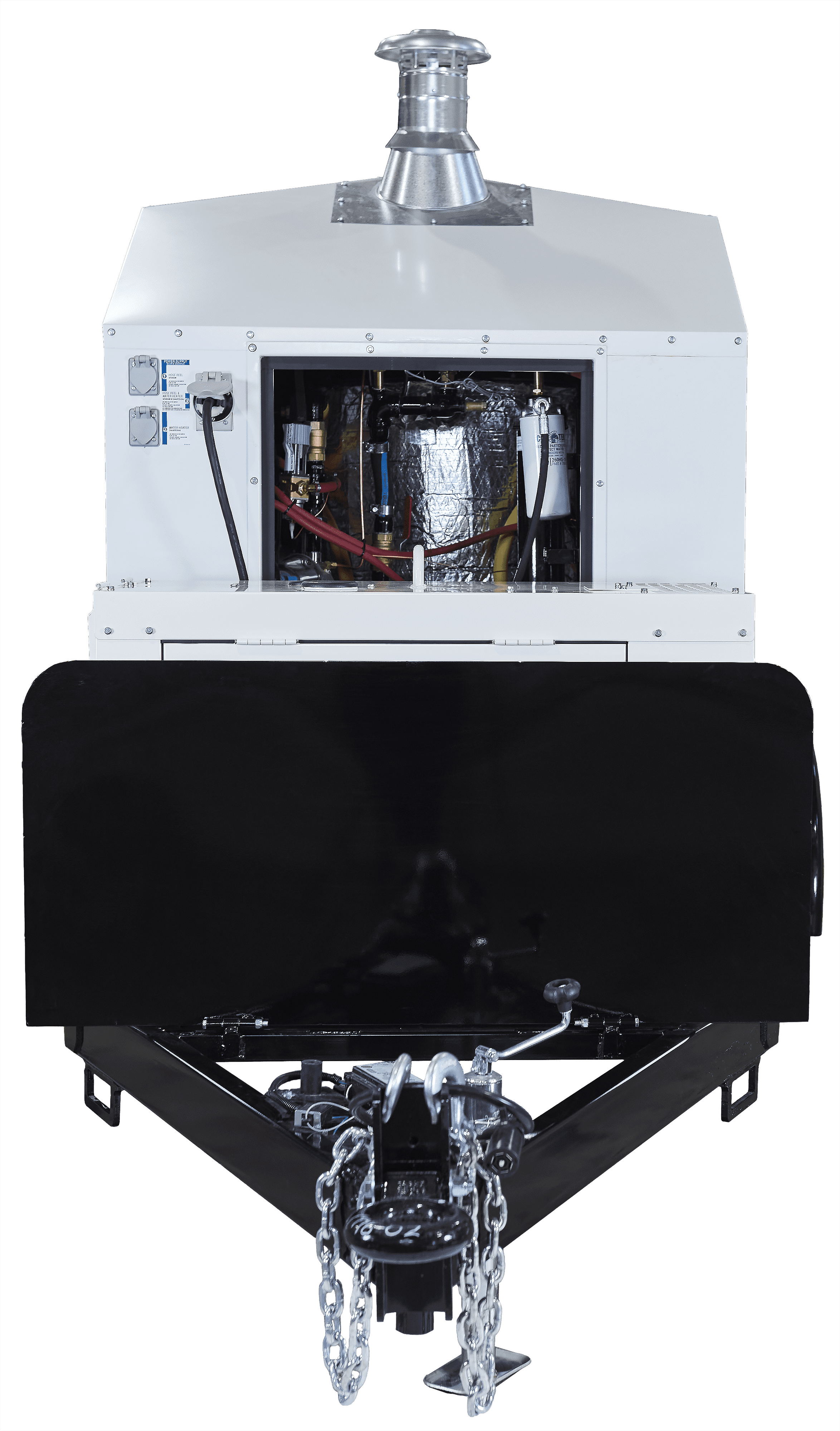

DryAir’s innovative CEC (combustion environment control) system preheats the combustion air and fuel to provide the burner with an ideal combustion environment in the widest range of ambient conditions.

Wide outside temperature swings will not affect the DryAir’s 400 GTS GreenThaw–it hums right along!

The hose reel is capable of carrying a total of 3,000 ft for more thawing or curing capacity.

DryAir’s enclosed design not only offers ease of operation and convenience, we also continue to honor our tradition of excellent service access to all components.

Combine the 400 GTS with DryAir accessories for specialty heating projects, including:

D-CAN 30 Desiccant Dehumidifier: Dry out flooded structures, or control humidity in buildings under construction to speed drying time of paint, mortar, specialty coatings, or drywall compound.

Fan Coils: Efficient heating for construction and renovation projects, provide an evenly heated, fume-free, low humidity environment.

HEFA 250EX Explosion Proof Fan Coil: 250,000 BTU’s of explosion proof space heating for oil & gas sites or industrial/mining applications where there is a risk of combustion from airborne gases or particles in the space.

Plate Heat Exchanger: Temporarily tie in to boiler systems while the permanent water heater is being replaced or down for maintenance.

Hose Reel & Thawing/Curing Hose: Wrap pipelines or fluid vessels to provide freeze protection.